HDI trimer HDT-100

ABOUT:

Tolonate™ HDT is a medium viscosity, solvent-free aliphatic polyisocyanate, used to produce 2K polyurethane coatings with superior performances.

BENEFITS:

-

Abrasion Resistance,

-

Hardness,

-

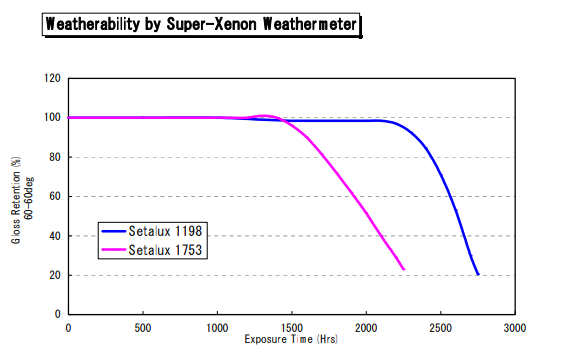

Weathering Resistance

APPLICATIONS:

-

Coatings & Adhesives,

-

Adhesives & Sealants,

-

Automotive OEM & refinish,

-

General Industry,

-

Transportation