Category: PU Technology

PU Technology

Chemical Catalysts: Enhancing Battery Performance and Lifespan

Commonly used products in the field of polyurethane foam

Application areas: polyurethane rigid foam, flexible foam, self-skinning, shoe materials

Characteristics: delayed, heat-sensitive

Function: prolonging emulsion time, prolonging drawing time

Use system: MDI/TDI/PAPI/mixed isocyanate

DY-215

Special amine delayed gel catalyst, providing excellent pre-flow, delaying drawing time, not affecting post-curing, accelerating product release.

DY-225

Diol solution of modified bis(dimethylaminoethyl) ether, delayed foaming catalyst, delayed emulsification time, improve fluidity, shorten demoulding time.

DY-300

Delayed gel catalyst, improve fluidity, good open porosity. Used for moulding high resilience, self-skinning, etc.

DY-400

Delayed foaming catalyst, can improve the carrying capacity of foam. Used in moulding high resilience, self-skinning, microcellular foaming, etc.

DY-8154

Modified triethylene diamine diol solution, gel catalyst with delayed action, can improve fluidity and shorten demoulding time.

Commonly used products in the field of polyurethane CASE

Application areas: polyurethane coatings, adhesives, elastomers, polyurethane acrylic coatings, fabric coatings, polyurethane pastes, leather finishes, composites, etc.

Characteristics: Delayed, heat-sensitive

Function: Extend the open time, delay the rise of viscosity, does not affect the post-curing

Use system: MDI/TDI/IPDI/HDI/H12MDI/ADI/XDI/mixed isocyanate

Delayed catalyst effect picture Introduction: In CASE field (adhesives, coatings, elastomers), the most commonly used catalyst is DY-12 (dibutyltin dilaurate), which has good selectivity to -NCO and -OH and high activity, but in the preparation of complex products, the operation time given to the workers is short, and it can’t satisfy the construction demand, in this condition, Shanghai Deyin Chemical Co. Ltd. has developed a series of delayed catalysts to recommend more suitable products for different isocyanate systems and construction conditions.

DY-5115

Used in polyurethane adhesives, coatings, elastomers, composites and other fields.

DY-5300

Used in polyurethane adhesives, coatings, elastomers, composites, etc.

DY-5320

Used in polyurethane elastomers, adhesives, sealants, elastic paints, leather finishing agents and other industries.

DY-5558

Used in one-component polyurethane adhesives, coatings, leather finishing agents and other industries

DY-5503

For polyurethane elastomers, adhesives, sealants, elastic paints, leather finishing agents and other industries

DY-5508

For polyurethane elastomers, adhesives, sealants, elastic paints, leather finishing agents and other industries

DY-5980

Used in polyurethane adhesives, leather finishing agents, coatings, microporous elastomers, etc.

DY-5982

Used in polyurethane adhesives, coatings, microporous elastomers, etc.

Recommended reading:

Addocat 106/TEDA-L33B/DABCO POLYCAT

Non-emissive polyurethane catalyst/Dabco NE1060 catalyst

NT CAT U26

NT CAT DMEA

High Quality N-(dimethylaminopropyl)diisopropanolamine / CAS 63469-23-8 / N-(3-dimethyl amino propyl)-N N-diisopropanolamine

Toyocat ETS Foaming catalyst Tosoh

BDMAEE Exporter

Jeffcat ZF-22

4-Acryloylmorpholine

NT CAT TMR-2

The Magic of Catalysts: Explaining How They Work

I. What is a catalyst?

A catalyst is a substance that speeds up the process of a chemical reaction, but is not involved in the chemical reaction itself. The addition of a catalyst can increase the efficiency of a chemical reaction by greatly reducing the time and temperature required for it to reach equilibrium.

Classification of catalysts

Catalysts are mainly divided into two categories: one is inorganic catalysts, such as metal catalysts, oxide catalysts, acid-base catalysts, etc.; and the other is organic catalysts, such as enzyme catalysts, biocatalysts and so on.

The working principle of catalyst

The working principle of catalyst is based on the adsorption and dissociation of reactants, as well as the intermediate formation and cleavage processes occurring on the catalyst surface. The following are the basic steps in the working principle of a catalyst:

1. adsorption: the catalyst is able to adsorb on the surface of reactant molecules, changing the charge distribution and molecular structure of the reactant molecules so that they are easy to undergo chemical reactions on the catalyst.

2. Activation: After adsorbing the reactants, the catalyst stimulates the molecules to undergo chemical reactions by providing electrons, dismantling chemical bonds, or triggering charge transfers between molecules so that the energy adsorbed by the reactants is reduced.

3. Reaction: the formation of intermediates on the surface of the catalyst and their reaction, i.e. the catalyst acts as a site for the reaction and facilitates the chemical change of the reactants into the desired product.

4. Dissociation: the resulting products leave the surface of the catalyst so that the catalyst can again adsorb new reactant molecules.

IV. Role of catalyst

As a special substance, catalyst can help reactant molecules combine and react more quickly and easily, in addition, catalyst also has the following roles:

1. reduce reaction activation energy: catalysts make it easier to combine reactant molecules into desired products by adsorption and activation of reactant molecules, and they can reduce the activation energy needed for the reaction and accelerate the reaction speed.

2. Improvement of reaction selectivity: catalysts can control the location and direction of the reaction so that a specific chemical reaction occurs without causing unnecessary side reactions.

3. Improvement of reaction efficiency: catalysts can increase the efficiency of the reaction, reduce reaction time and energy consumption, save raw materials and accelerate the preparation of products.

V. Conclusion

Catalysts play a vital role in chemical reactions. Through the process of adsorption, activation, reaction and dissociation, catalysts can accelerate the chemical reaction, improve the reaction efficiency and increase the reaction selectivity, which makes the chemical synthesis more accurate and efficient. Therefore, catalysts have become an important and indispensable part of the modern chemical industry.

Related reading:

NT CAT K-15

2-(2-Aminoethoxy)ethanol

Dabco NE1060/Non-emissive polyurethane catalyst

High efficiency amine catalyst/Dabco amine catalyst

NT CAT BDMA

NT CAT PC-8

N-Ethylmorpholine

Bismuth 2-Ethylhexanoate

High Quality BDMA / 103-83-3 / Benzyldimethylamine / N,N-dimthylbenzylamine

Toyocat ETS Foaming catalyst Tosoh

Jeffcat ZF-22

Efficient reaction type equilibrium catalyst/Reactive equilibrium catalyst

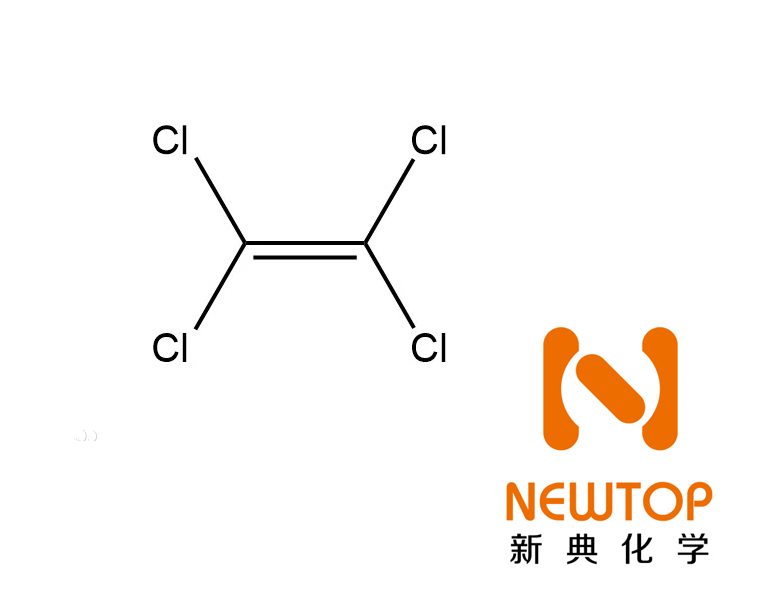

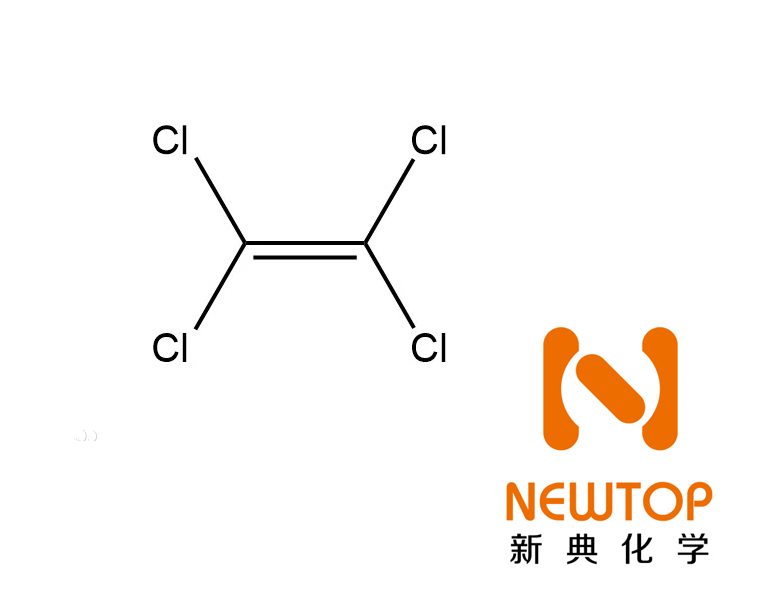

Tetrachloroethylene Perchloroethylene CAS:127-18-4

Tetrachloroethylene Perchloroethylene CAS:127-18-4

Perchloroethylene, also known as perchloroethylene, is an organic compound with the chemical formula C2Cl4 and is a colorless liquid.

Chinese name: tetrachloroethylene

Foreign name: tetrachloroethene

Alias: perchloroethylene

Chemical formula C2Cl4

Molecular weight 165.833

CAS No. 127-18-4

EINECS No. 204-825-9

Melting point-22 ℃

Boiling point 121 ℃

Water solubility

Density1.622 g/cm³

Appearance Colorless liquid

Safety Description S7; S16; S23; S24; S36/37; S45; S61

Hazard symbol Xn

Hazard description R40; R51/53

Physical and chemical properties

Density: 1.622g/cm3

Melting point: -22℃

Boiling point: 121℃

Refractive index: 1.505 (20℃)

Saturated vapor pressure: 2.11kPa (20℃)

Critical temperature: 347.1℃

Critical pressure: 9.74MPa

Appearance: colorless liquid

Solubility: insoluble in water, miscible in most organic solvents such as ethanol, ether, chloroform, etc.

Uses: Mainly used as organic solvent, dry cleaning agent.

Mainly used as organic solvent, dry cleaning agent, also can be used as solvent for adhesive, degreasing solvent for metal, desiccant, paint stripper, insect repellent, fat extractant, also can be used in organic synthesis.

Storage and transportation:

It should be sealed and stored in dry, cool and ventilated warehouse

Packing:

200KG/drum Storage: it is recommended to store in dry and cool area with proper ventilation. After the original packaging, please fasten the packaging cover as soon as possible to prevent moisture and other substances from mixing and affecting the performance of the product. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

Dabco NE1060/Non-emissive polyurethane catalyst

Dabco NE1060/Non-emissive polyurethane catalyst

Overview:

Product name: Dabco NE1060 catalyst

Alias: Dabco NE1060 Catalyst, Dabco NE1060, Foam Catalyst Dabco NE1060, Non-emitting Polyurethane Catalysts

Product Description: Dabco NE1060 Catalyst for Flexible Molded Polyurethane Foams

Description.

Dabco NE1060 catalyst is a new, second generation, non-emission (NE) gel catalyst for diphenylmethylene diisocyanate (MDI) and toluene diisocyanate (TDI) polyurethane expanded flexible molded foams Dabco NE1060 catalyst maintains the foam properties while forming a Dabco NE1060 catalysts maintain foam properties while forming a strong chemical bond with the polyurethane foam matrix. Used in automotive manufacturing, this product eliminates the odor and VOC emissions associated with polyurethane catalysts that cause windshield fogging and beading and staining of polyethylene plastics.

Typical Physical Properties.

Appearance Colorless transparent liquid

Specific gravity 1.06

Viscosity @25℃ mPa.s 1200

Water solubility @25℃ completely dissolved

Flash point, ℃ 168

Characteristics

1、Non emitting polyurethane catalyst

2、Non emission of volatile organic compounds

3、No staining of polyethylene plastic

4、Does not let windshield fog and water droplets appear

-

Stabilized masterbatch

6、Reduce odor

7、Control the stability between batches

Recommendations for Use.

Dabco NE1060 catalyst is recommended for use in TDI or TDI/MDI polyurethane high resilient (HR) foams, as well as TDI/MDI-based or MDI-based polyurethane cold cure molded foams, and polyurethane liner foam systems. This non-volatile catalyst is compatible with other commonly used polyurethane catalysts and additives and is highly miscible with polyols and polyol-water mixtures.

Dabco NE1060 catalyst is recommended for use at levels of 0.50 to 1.50 pphp in MDI systems and 0.40 to 0.70 pphp in TDI systems.

Shelf Life.

Keep unopened for two years

Storage and Transportation:

Should be kept sealed and stored in a dry, cool, ventilated warehouse

Packaging:

200KG/drum Storage: it is recommended to store in dry and cool area with proper ventilation. Please fasten the packaging cover as soon as possible after the original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the product performance. Store in a cool and dry place, keep the container sealed and avoid contact with oxides. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothing separately and wash before use. Maintain good hygiene practices. The company recommends that all polyurethane catalysts be stored in a dry, cool and properly ventilated area. All storage containers must be well sealed to avoid contact with water or other affected substances, which may alter the performance of the product in use. The storage temperature is 10°C to 30°C. Lower or higher temperatures are inappropriate and should be avoided if possible.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

[email protected] |

Telephone: |

86-021-5657 7831 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |

Non-emissive polyurethane catalyst/Dabco NE1060 catalyst

Non-emissive polyurethane catalyst/Dabco NE1060 catalyst

Overview:

Product name: Dabco NE1060 catalyst

Alias: Dabco NE1060 Catalyst, Dabco NE1060, Foam Catalyst Dabco NE1060, Non-emitting Polyurethane Catalysts

Product Description: Dabco NE1060 Catalyst for Flexible Molded Polyurethane Foams

Description.

Dabco NE1060 catalyst is a new, second generation, non-emission (NE) gel catalyst for diphenylmethylene diisocyanate (MDI) and toluene diisocyanate (TDI) polyurethane expanded flexible molded foams Dabco NE1060 catalyst maintains the foam properties while forming a Dabco NE1060 catalysts maintain foam properties while forming a strong chemical bond with the polyurethane foam matrix. Used in automotive manufacturing, this product eliminates the odor and VOC emissions associated with polyurethane catalysts that cause windshield fogging and beading and staining of polyethylene plastics.

Typical Physical Properties.

Appearance Colorless transparent liquid

Specific gravity 1.06

Viscosity @25℃ mPa.s 1200

Water solubility @25℃ completely dissolved

Flash point, ℃ 168

Characteristics

1、Non emitting polyurethane catalyst

2、Non emission of volatile organic compounds

3、No staining of polyethylene plastic

4、Does not let windshield fog and water droplets appear

-

Stabilized masterbatch

6、Reduce odor

7、Control the stability between batches

Recommendations for Use.

Dabco NE1060 catalyst is recommended for use in TDI or TDI/MDI polyurethane high resilient (HR) foams, as well as TDI/MDI-based or MDI-based polyurethane cold cure molded foams, and polyurethane liner foam systems. This non-volatile catalyst is compatible with other commonly used polyurethane catalysts and additives and is highly miscible with polyols and polyol-water mixtures.

Dabco NE1060 catalyst is recommended for use at levels of 0.50 to 1.50 pphp in MDI systems and 0.40 to 0.70 pphp in TDI systems.

Shelf Life.

Keep unopened for two years

Storage and Transportation:

Should be kept sealed and stored in a dry, cool, ventilated warehouse

Packaging:

200KG/drum Storage: it is recommended to store in dry and cool area with proper ventilation. Please fasten the packaging cover as soon as possible after the original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the product performance. Store in a cool and dry place, keep the container sealed and avoid contact with oxides. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothing separately and wash before use. Maintain good hygiene practices. The company recommends that all polyurethane catalysts be stored in a dry, cool and properly ventilated area. All storage containers must be well sealed to avoid contact with water or other affected substances, which may alter the performance of the product in use. The storage temperature is 10°C to 30°C. Lower or higher temperatures are inappropriate and should be avoided if possible.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

[email protected] |

Telephone: |

86-021-5657 7831 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |

High efficiency amine catalyst/Dabco amine catalyst

High efficiency amine catalyst/Dabco amine catalyst

Overview:

Product Name: Dabco RP205

Alias: Dabco RP205, Addocat 9727P, high efficient amine catalyst, Dabco amine catalyst, low density sponge catalyst Dabco RP205

Product Description: High efficient amine catalyst for low density (below 10kg\\\m³) sponges, with good operating tolerance and foam stabilization effect, it can replace the similar product SMP, which plays the role of amine catalyst. Has the ability to increase hardness. Used in the manufacture of low density flexible slabstock foam, it can provide wide process latitude.

Profile:

RP-205 is an amine catalyst developed for “dichloromethane formulations” (content >20), which is suitable for the production of low density (less than 10 kg/m3) slabstock foams.

RP-205 has a high catalytic capacity and high catalytic activity.

Compared to conventional amine catalysts, catalyst RP-205 provides good operating latitude and foam stabilization during the foaming process.

Compared with the same type of amine catalyst in the market, Catalyst RP-205 can increase the sponge hardness.

It is easy to use and can be directly replaced by customers using the same type of amine catalyst (within 10% difference in dosage).

Points for use: When using RP-205, it is recommended to pay attention to the following points:

RP-205 is recommended to be used as a separate amine catalyst.

-

It is recommended that the original amount of amine catalyst used be replaced by 1:1, and then fine-tuned according to actual needs. (It is recommended that the fine-tuning range is within 10% of the amine dosage.)

3、Catalyst RP-205 can be used directly for dosing or pre-mixed with polyether, the mixing ratio can be 1:5 to 1:12 or lower.

4、When catalyst RP-205 is mixed with polyether polyol, the storage period of the mixture should not exceed 12 hours. (Use up on the same day)

5、Because of the low vapor pressure of RP-205, the package should be sealed immediately after use to avoid volatilization and failure.

Shelf life.

Keep unopened for two years

Storage:

Should be sealed and stored in a dry, cool and ventilated warehouse

Packaging:

200KG/drum Storage: it is recommended to store in dry and cool area with proper ventilation. Please fasten the packaging cover as soon as possible after the original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the product performance. Store in a cool and dry place, keep the container sealed and avoid contact with oxides. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothing separately and wash before use. Maintain good hygiene practices. The company recommends that all polyurethane catalysts be stored in a dry, cool and properly ventilated area. All storage containers must be well sealed to avoid contact with water or other affected substances, which may alter the performance of the product in use. The storage temperature is 10°C to 30°C. Lower or higher temperatures are inappropriate and should be avoided if possible.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

[email protected] |

Telephone: |

86-021-5657 7831 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |

Dabco amine catalyst/Low density sponge catalyst

Dabco amine catalyst/Low density sponge catalyst

Overview:

Product Name: Dabco RP205

Alias: Dabco RP205, Addocat 9727P, high efficient amine catalyst, Dabco amine catalyst, low density sponge catalyst Dabco RP205

Product Description: High efficient amine catalyst for low density (below 10kg\\\m³) sponges, with good operating tolerance and foam stabilization effect, it can replace the similar product SMP, which plays the role of amine catalyst. Has the ability to increase hardness. Used in the manufacture of low density flexible slabstock foam, it can provide wide process latitude.

Profile:

RP-205 is an amine catalyst developed for “dichloromethane formulations” (content >20), which is suitable for the production of low density (less than 10 kg/m3) slabstock foams.

RP-205 has a high catalytic capacity and high catalytic activity.

Compared to conventional amine catalysts, catalyst RP-205 provides good operating latitude and foam stabilization during the foaming process.

Compared with the same type of amine catalyst in the market, Catalyst RP-205 can increase the sponge hardness.

It is easy to use and can be directly replaced by customers using the same type of amine catalyst (within 10% difference in dosage).

Points for use: When using RP-205, it is recommended to pay attention to the following points:

RP-205 is recommended to be used as a separate amine catalyst.

-

It is recommended that the original amount of amine catalyst used be replaced by 1:1, and then fine-tuned according to actual needs. (It is recommended that the fine-tuning range is within 10% of the amine dosage.)

3、Catalyst RP-205 can be used directly for dosing or pre-mixed with polyether, the mixing ratio can be 1:5 to 1:12 or lower.

4、When catalyst RP-205 is mixed with polyether polyol, the storage period of the mixture should not exceed 12 hours. (Use up on the same day)

5、Because of the low vapor pressure of RP-205, the package should be sealed immediately after use to avoid volatilization and failure.

Shelf life.

Keep unopened for two years

Storage:

Should be sealed and stored in a dry, cool and ventilated warehouse

Packaging:

200KG/drum Storage: it is recommended to store in dry and cool area with proper ventilation. Please fasten the packaging cover as soon as possible after the original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the product performance. Store in a cool and dry place, keep the container sealed and avoid contact with oxides. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothing separately and wash before use. Maintain good hygiene practices. The company recommends that all polyurethane catalysts be stored in a dry, cool and properly ventilated area. All storage containers must be well sealed to avoid contact with water or other affected substances, which may alter the performance of the product in use. The storage temperature is 10°C to 30°C. Lower or higher temperatures are inappropriate and should be avoided if possible.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

[email protected] |

Telephone: |

86-021-5657 7831 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |

Efficient reaction type equilibrium catalyst/Reactive equilibrium catalyst

Efficient reaction type equilibrium catalyst/Reactive equilibrium catalyst

Overview:

Product Name: Dabco RP208 High Efficiency Reactive Balancing Catalyst

Alias: Dabco RP208, high efficiency reactive equilibrium catalyst, reactive equilibrium catalyst, low odor reactive equilibrium catalyst, high resilience sponge reactive equilibrium catalyst

Product Description: Dabco RP208 High Efficiency Reactive Equilibrium Catalyst is suitable for the production of low odor, low VOC soft sponges, and is recommended to be used in medium and high density ordinary sponges, high resilience and slow resilience sponges.

Availability: Yes Type: Others

Use: High resilience, slow resilience sponge Model: Dabco RP208

Specification: 25kg / barrel Trademark: Airborne Chemicals

Packing: Barrel Supplier: XinDian Chemical

Capacity: 2000

Introduction:

Brand: Air Chemical

Model: RP205

Product Name: Amine Catalyst

Main Ingredients: Catalyst

Use: Low VOC soft sponge

Useful life: slow rebound sponge

Use temperature:/℃

Specific surface area: /m2/kg

Heap density: /kg/m3

Water absorption: /%

Overall size: barrel

Packing specification: 25kg/drum

Role:

Odorless and high efficient reactive balanced catalyst for the production of low odor and low VOC soft sponges, suitable for medium and high density ordinary sponges, high resilience and slow resilience sponges.

Shelf life.

Keep unopened, two years

Storage and transportation:

Should be sealed and stored in dry, cool and ventilated warehouse

Packing:

200KG/drum Storage: it is recommended to store in dry and cool area with proper ventilation. Please fasten the packaging cover as soon as possible after the original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the product performance. Store in a cool and dry place, keep the container sealed and avoid contact with oxides. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothing separately and wash before use. Maintain good hygiene practices. The company recommends that all polyurethane catalysts be stored in a dry, cool and properly ventilated area. All storage containers must be well sealed to avoid contact with water or other affected substances, which may alter the performance of the product in use. The storage temperature is 10°C to 30°C. Lower or higher temperatures are inappropriate and should be avoided if possible.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

[email protected] |

Telephone: |

86-021-5657 7831 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |