High Quality TMR-2 / CAS 62314-25-4 / 2-HYDROXYPROPYLTRIMETHYLAMMONIUMFORMATE

Overview:

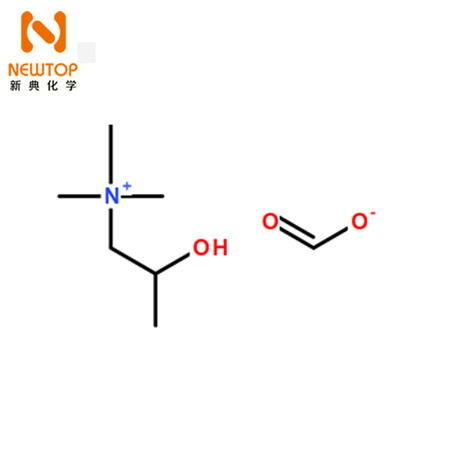

Chinese name: 2-Hydroxy-N,N,N-trimethyl-1-propanamine formate

Alias: Catalyst TMR-2, Polyurethane Catalyst TMR-2, TMR-2, Hard Foam Catalyst TMR-2, Trimerization Catalyst TMR-2, Dabco TMR-2, Formate of 2-Hydroxy-N,N,N-Trimethyl-1-Propylamine, Toyocat TRV, Dabco Catalysts, Dabco Trimerization Catalysts, Semi-Hard Foam Catalysts, Semi-Hard Foam Catalyst TMR-2, Hard Bubble Catalyst TMR-2, Trimerization Catalyst TMR-2

English name: 1-Propanaminium-2-hydroxy-N,N,N-trimethylformate

Physicochemical properties:

2-hydroxy-N,N,N-trimethyl-1-Propanaminium formate is transparent colorless liquid, soluble in water.

Viscosity(25℃,mPa.s):190

Density (25℃,g/cm3): 1.07

Water solubility: slightly soluble in water

Flash point (PMCC,℃): 121

Hydroxyl value (mgKOH/g): 463

Molecular formula: C7H17NO3

Molecular weight: 163.21

CAS No.: 62314-25-4

Catalyst TMR-2 Tripolymerization Catalyst Polyurethane Catalyst TMR-2 TMR-2 Rigid Foam Catalyst TMR-2 Tripolymerization Catalyst TMR-2 Dabco TMR-2 Formate of 2- Hydroxy-N,N,N-trimethyl-1-propanamine Toyocat TRV Dabco Catalysts Dabco Tripolymerization Catalysts Semi-Rigid Foam Catalyst Semi-Rigid Foam Catalysts TMR-2 Rigid Foam Catalyst TMR-2 Trimerization Catalyst TMR-2

Applications:

2-Hydroxy-N,N,N-trimethyl-1-propanamine formate is a tertiary amine catalyst used to promote polyisocyanurate reactions (trimerization); 2-Hydroxy-N,N,N-trimethyl-1-propanamine formate provides uniform control of the initiation reaction compared to potassium catalysts.

Product Usage:

Dabco TMR-2 is a tertiary amine catalyst used to promote polyisocyanurate reactions (trimerization). It provides uniform control of the initiation reaction compared to potassium catalysts;

Dabco TMR-2 catalyst is used in rigid foam applications and provides better flow than Dabco TMR catalyst and can also be used in post-curing of flexible molded foam applications.

DABCO TMR-2 is used in polyisocyanurate (PIR) applications but is milder and reduces the release time of rigid foams; it is mainly used in polyurethane rigid foams such as panels, refrigerator composites, etc. DABCO TMR-2 catalyst is a quaternary amine catalyst mainly used in the production of polyurethane rigid foams and has the ability to improve the mechanical and processability of the foams, shorten the curing time of the foams, reduce -NCO residues in the foams, and reduce the -NCO content in the foams. The catalyst is mainly used in the production of polyurethane rigid foams.

DABCO TMR-2 is a quaternary catalyst with low dosage. The catalyst dosage is 1%-5% of the isocyanate. It can be used in various rigid foam systems such as polyurethane and polyisocyanate, etc. It can be used as a high-temperature catalyst by forming an isocyanurate ring at 20°C or higher. It has good mutual solubility with isocyanate and other raw materials.

Storage and transportation:

It should be sealed and stored in dry, cool and ventilated warehouse.

Packing:

180KG/drum Storage: it is recommended to store in dry and cool area with proper ventilation. Please fasten the package cover as soon as possible after the original packaging to prevent moisture and other substances from mixing and affecting the performance of the product. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

[email protected] |

Telephone: |

86-021-5657 7831 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |