Polyurethane triazine catalyst/Jeffcat TR-90

Overview:

Name: Polyurethane hard foam catalyst

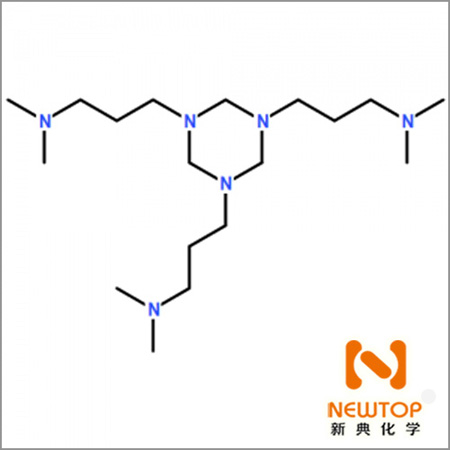

Polyurethane Hard Foam Catalyst PC41 is a colorless to light yellow transparent liquid with a very faint odor or nearly odorless, easily soluble in water.PC-41 is a chemical substance with the molecular formula C18H42N6.

Catalyst PC-41 is a chemical substance, the molecular formula is C18H42N6.

Chinese name: 1,3,5-Tris(dimethylaminopropyl)hexahydrotriazine, short for triazine

Alias: Catalyst PC-41, Catalyst PC41, Polyurethane Catalyst PC41, Polyurethane Catalyst PC41, Rigid Foam Catalyst PC41, Rigid Foam Catalyst PC-41, Trimerization Catalyst PC-41, Trimerization Catalyst PC41, Tricine Catalyst, Toyocat TRC, Polyurethane Tricine Catalyst, Tris(dimethylaminopropyl) Hexahydrotricine, Hexahydrotricine. CAS 15875-13-5, 15875-13-5, Polycat 41, Jeffcat TR-90, Lupragen N600, Tegoamin 41, PC CAT NP40, Hard foam catalyst PC41, Semi-hard foam catalyst PC41, Shoe sole catalyst PC41, Triazine catalyst PC41

English name: 1,3,5-Tris[3-(dimethylamino)propyl]hexahydro-1,3,5-triazine

Molecular Formula:C18H42N6

Molecular Weight: 342.0

CAS No.: 15875-13-5

Chinese name PC-41

Molecular Formula C18H42N6

CAS No. 15875-13-5

Relative Molecular Weight 342

Chemical composition Tris(dimethylaminopropyl)hexahydrotriazine, short for triazine

Alias Catalyst PC-41, Catalyst PC41, Polyurethane Catalyst PC41, Polyurethane Catalyst PC-41, Rigid Foam Catalyst PC41, Rigid Foam Catalyst PC-41, Trimerization Catalyst PC-41, Trimerization Catalyst PC41, Tricine Catalyst, Toyocat TRC, Polyurethane Tricine Catalyst, Tris(dimethylaminopropyl) Hexahydrotricine, Hexahydrotricine. CAS 15875-13-5, 15875-13-5, Polycat 41, Jeffcat TR-90, Lupragen N600, Tegoamin 41, PC CAT NP40, Hard foam catalyst PC41, Semi-hard foam catalyst PC41, Shoe sole catalyst PC41, Tricat catalyst PC41

Profile:

Relative density: 0.92-0.95

Viscosity (25℃): 26-33mP.s

Flash Point: 153°C (COC) or 132°C (TMCC)

Boiling point: 255℃ or 140℃/133Pa

Freezing point: -59℃

Vapor pressure (21℃): 13Pa

Physical and Chemical Properties:

The product is colorless to light yellow transparent liquid with very weak odor or nearly odorless, easily soluble in water.

Relative density 0.92~0.95

Viscosity(25℃)26~33mPa.s

Flash point 153℃(COC) or 132℃(TMCC)

Boiling point 225℃ or 140℃/133Pa

Freezing point -59℃

Vapor pressure(21℃)13Pa

Moisture in product ≤0.5%

Nitrogen content 17%~18

Uses:

PC41 Highly active trimerization catalyst for polyurethane hard foams with excellent foaming/gelling ability, usually shared with other catalysts.

PC41 is mainly used to catalyze polyurethane and polyisocyanate reactions, in fact, the catalytic selective activity of polyurethane is slightly higher than that of polyisocyanate reactions, and is commonly used in polyurethane rigid foams for laminated sheets, sprayed rigid foams, and molded rigid foams;

PC41 is more suitable for polyisocyanate rigid foam sheet, all kinds of foaming agent foaming (including all-water foaming) and other processes, and has excellent performance in water foaming rigid foam system;

PC41 is also suitable for microcellular polyurethane elastomer and high resilience foam products.

Storage and transportation:

It should be sealed and stored in dry, cool and ventilated warehouse

Packaging:

200KG/drum Storage: it is recommended to store in dry and cool area with proper ventilation. Please fasten the packaging cover as soon as possible after the original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the product performance. Store in a cool and dry place, keep the container sealed and avoid contact with oxides. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothing separately and wash before use. Maintain good hygiene practices.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

[email protected] |

Telephone: |

86-021-5657 7831 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |