Author: admin

Toyocat TE tertiary amine catalyst Tosoh

Toyocat TE tertiary amine catalyst Tosoh

Overview:

Toyocat TE is a tertiary amine-based foaming catalyst that facilitates urea (water-isocyanate) reactions in a variety of hard and soft polyurethane foam applications. It is the industry standard foaming catalyst for soft foams and is used in TDI-based soft foam systems such as mattresses, seats and automobiles. It is also used in combination with trimer catalysts in PIR laminated paperboard formulations. Toyocat TE is also available in MDI, TDI/MDI, MDI High Resilience (HR) soft molding foams as well as self-crusting and microcellular systems. It has a shelf life of 36 months.

CAS No.

The CAS number for Toyocat TE is 110-18-9. This is a unique identifier for Toyocat TE that is used to track and identify it throughout the supply chain. CAS numbers are also used to search databases and other resources for information about Toyocat TE.

Description: Tetramethylenediamine is an organic amine catalyst for polyurethanes

Alias: tetramethyleneethylenediamine, 1, 2-bis (dimethylamino) ethane

Molecular formula: C6H16N2

Molecular weight: 116

CAS number: 110-18-9

English name: N, N, N, N – tetramethylethylenediamine

Other brands: TMEDA; Toyocat TE; Kaolizer 11 etc.

Physical and chemical properties

The physical and chemical properties of Toyocat TE are shown in the following table:

<table class=”MsonormalTable ke-zeroborder” border=”0″ cellspacing=”2″ style=”width:431.2500pt;”>

Property

Value

appearance

Clear colorless liquid

Scent

A slight ammonia smell

Specific gravity

1.040

Boiling point

200 ℃

Flash point

100 ℃

Water soluble

Miscible

Solubility in organic solvents

miscibility

Features

Promotes urea (water-isocyanate) reaction

For a variety of rigid and soft polyurethane foam applications

Industry standard foaming catalyst for soft foams

For TDI-based soft foam systems, such as mattresses, seats, and automobiles

Use in combination with trimer catalysts in PIR laminated cardboard formulations

Also available in MDI, TDI/MDI, MDI High Resilience (HR) soft molded foams as well as self-crusting and microcellular systems

The shelf life is 36 months

Leak treatment

Stop leaks as much as possible while ensuring safety. If a minor leak is found, treat it with sand or other absorbent material and place it in a clean, dry container for subsequent treatment. If a large amount of leakage occurs, the leaked material should be collected for subsequent treatment. Avoid material entering groundwater or surface water, because it is not easily degraded by biological matter. All collected leakage materials should be disposed of in accordance with the relevant regulations of the local environmental protection department.

Disclaimer

The information and technical advice provided above are obtained from reliable sources. However, the data provided by us is without express or implied warranties, and no commitments are made herein. If you need to use our products, we recommend a series of tests. The application, use, processing or production of products based on the technical information provided by us is outside our control and therefore the responsibility lies with the user. Conditions and methods of handling, storage, use or disposal of this product are beyond our control and may be beyond our knowledge, and under no circumstances will we be liable for loss, damage or related expenses arising from improper handling, storage, use or disposal of this chemical. For more information, please review the technical safety specifications of our products or contact our Marketing Services department.

Safety Information:

Catalyst, rinse with soapy water promptly after contact with skin. The staff can wear an eye mask or safety glasses to achieve the purpose of eye protection. Eye washing and bathing facilities should be available near the workplace. When working in places that may come into contact with the product, you should pay attention to personal hygiene and use detergent to wash the skin in contact with the product before eating, smoking and leaving the work.

Shelf life:

Remain unopened for two years

Storage and Transportation:

Should be sealed, stored in a dry cool ventilated warehouse

Packaging:

200KG/ barrel storage: It is recommended to store in a dry and cool area with proper ventilation. After the original packaging, please fasten the packaging cover as soon as possible to prevent moisture and other substances from mixing and affecting the product performance. Do not inhale dust and avoid contact between skin and mucous membrane. Smoking, eating and drinking are prohibited in the workplace. Shower and change after work. Store contaminated clothes separately and use them after washing. Practice good hygiene.

Technical support and business contacts E-mail:[email protected]

HDI Low Viscosity AsahiKasei TUL-100

HDI Low Viscosity AsahiKasei TUL-100

ABOUT:

Product Class: Isocyanate

DURANATE TUL-100 by Asahi Kasei is hexamethylene diisocyanate (HDI) trimer with extra-low viscosity and high NCO content. Acts as a curing agent for urethanes. Exhibits excellent weatherability, good chemical & abrasion resistance, good compatibility and drying properties. Shows excellent color retention and outstanding performance. DURANATE TUL-100 is suitable for automotive, architectural, industrial, consumer electronic and information technology Possible applications could be gravure, offset and screen inks.

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

HDI Low Viscosity AsahiKasei TLA-100

HDI Low Viscosity AsahiKasei TLA-100

Type:

Aliphatic polyisocyanate based on hexamethylene diisocyanate.

Features:

# High NCO content

# Low viscosity

# Excellent weather resistance

# Excellent Compatibility

# Good coating film appearance

Applications:

# Two-component applications

# Automotive OEM coatings

# Automotive refinishes

# Plastic coatings

Typical properties:

Appearance |

Colorless to slightly yellowish clear liquid |

Non-volatile |

100 wt% |

Solvent |

None |

NCO content |

23.5 wt% |

Viscosity |

500 mPa·s at 25’C |

Color value |

< 1 (Gardner) |

NCO equivalent weight |

Approx.180 |

These values provide general information and are not part of the productspecifications.

Comparison with Conventional Trimer:

TLA-100 |

Conv Trimer |

|

Viscosity mPa * s/25℃ |

500 |

2,700 |

NCO content % |

23.5 |

21.7 |

Functionality |

3.0 |

3.4 |

HDI conc. After 50℃ . 1 month |

Low |

Low |

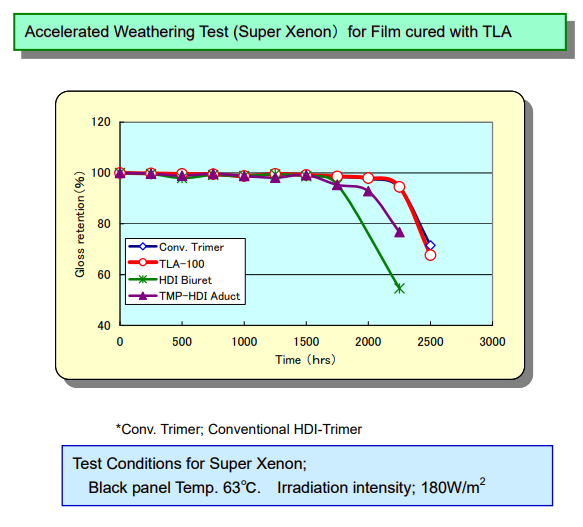

Weather resistance of cured film |

Excellent |

Excellent |

Hardness of cured film |

High |

High |

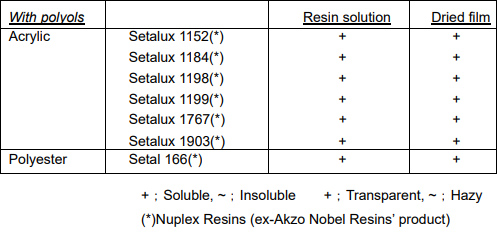

Compatibility with polyols:

Mixing ratio of DURANATETM TLA-100 with polyols is based on NCO/OH equivalentratio of 1/1 .

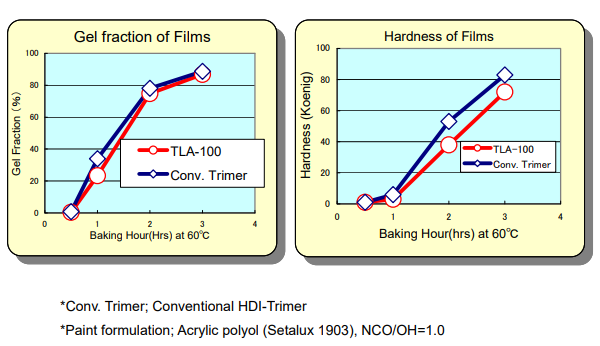

Development of gel fraction & hardness:

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

HDI Waterborne Covesro XP2655

HDI Waterborne Covesro XP2655

ABOUT:

Hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI).Hardener for waterborne two-component polyurethane systems.

Product Types

-

HDI

-

PIC

-

Hydrophilic polyisocyanate

-

Aliphatic polyisocyanate

-

Crosslinkers

-

Polyisocyanate

-

Hardeners

-

Polyisocyanurate

-

Isocyanate

-

Reactive system

Material:

Coatings, paints & inks:Fast curing, Weather resistant, Easy mixing, Waterborne

Adhesives:Moisture resistant, Fast bonding, Waterborne, Heat activated

General Characterization:

Hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI).

Hardener for waterborne two-component polyurethane systems.

Logistics and Handling

Storage Conditions:

– Storage in original sealed Covestro container.

– Recommended storage temperature: 0 – 30 °C.

– Protect from moisture, heat and foreign material.

General information: Hydrophilic isocyanates are very moisture-sensitive and react with water to form carbon dioxide and insoluble ureas. The containers must always be kept tightly closed. The access of water in all forms (moist air, solvents, moist containers) must be prevented, because the generation of carbon dioxide can lead to dangerous increases in pressure. Storage at higher temperatures will result in increase of color and viscosity.

Sampling:

No data available

Technical Properties & Datasheets

Characteristics:

Property Name |

Test Method |

Unit |

Value |

Flash point |

DIN EN ISO 2719 |

°C |

approx. 192 |

Density |

DIN EN 2811 |

g/cm3 |

approx. 1.16 |

Specifications:

Property Name |

Test Method |

Unit |

Value |

Viscosity at 23 °C |

M014-ISO 3219/A.3 |

mPa*s |

3,500 ± 1,000 |

NCO content |

M105-ISO 11909 |

% |

20.3 – 21.3 |

Hazen color value |

M017-EN 1557 |

< 60 |

|

Monomeric HDI |

M106-ISO 10283 |

% |

≤ 0.24 |

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

HDI Waterborne Covesro XP2547

HDI Waterborne Covesro XP2547

ABOUT:

Hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI). Hardener for waterborne two-component polyurethanecoatings.

Product Types:

No data available

Material:

No data available

General Characterization:

Hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI).

Hardener for waterborne two-component polyurethane coatings.

Logistics and Handling

Storage Conditions:

– Storage in original sealed Covestro container.

– Recommended storage temperature: 0 – 30 °C.

– Protect from moisture, heat and foreign material.

General information: Hydrophilic isocyanates are very moisture-sensitive and react with water to form carbon dioxide and insoluble ureas. The containers must always be kept tightly closed. The accessof water in all forms (moist air, solvents, moist containers) must be prevented, because the generation of carbon dioxide can lead todangerous increases in pressure. Storage at higher temperatures will result in increase of color and viscosity.

Sampling:

No data available

Technical Properties & Datasheets

Characteristics:

Property Name |

Test Method |

Unit |

Value |

Density at 20 °C |

DIN EN ISO 2811 |

g/ml |

approx. 1.15 |

Flash point |

DIN EN 22 719 |

°C |

approx. 185 |

Specifications:

Property Name |

Test Method |

Unit |

Value |

Hazen color value |

M017-EN 1557 |

≤ 150 |

|

Monomeric HDI |

M016-ISO 10283 |

% |

< 0.26 |

NCO content |

M105-ISO 11909 |

% |

22.5 ± 0.5 |

Viscosity at 23 °C |

M014-ISO 3219/A.3 |

mPa*s |

570 – 730 |

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

HDI Waterborne Covesro 305

HDI Waterborne Covesro 305

ABOUT:

Hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI).As a hardener for aqueous two-component polyurethane systems.

Product Types:

Hydrophilic polyisocyanate

Material:

No data available

General Characterization:

Hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI).

As a hardener for aqueous two-component polyurethane systems.

Logistics and Handling

Storage Conditions:

– Storage in original sealed Covestro container.

– Recommended storage temperature: 0 – 30 °C.

– Protect from moisture, heat and foreign material.

General information: Hydrophilic isocyanates are very moisture-sensitive and react with water to form carbon dioxide and insoluble ureas. The containers must always be kept tightly closed. The accessof water in all forms (moist air, solvents, moist containers) must be prevented, because the generation of carbon dioxide can lead todangerous increases in pressure. Storage at higher temperatures will result in increase of color and viscosity.

Sampling:

No data available

Technical Properties & Datasheets

Characteristics:

Property Name |

Test Method |

Unit |

Value |

Density |

DIN 53 217 |

g/cm3 |

approx. 1.16 |

Equivalent weight |

approx. 260 |

||

Flash point |

DIN EN 53 213 |

°C |

approx. 230 |

Specifications:

Property Name |

Test Method |

Unit |

Value |

Hazen color value |

DIN EN 1557 |

≤ 150 |

|

NCO content |

DIN EN ISO 11 909 |

% |

16.2 ± 0,4 |

Monomeric HDI content |

DIN EN ISO 10 283 |

% by wt. |

< 0.15 |

Viscosity at 23 °C |

DIN EN ISO 3219/A.3 |

mPa*s |

6,500 ± 1,500 |

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

HDI Waterborne Covesro 304

HDI Waterborne Covesro 304

ABOUT:

Hydrophilically modified, aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI). As the hardener/binder component for high-quality waterborne polymer dispersions and as an additive to improve the property level of waterborne coating and adhesive systems.

Product Types

-

HDI

-

PIC

-

Hydrophilic polyisocyanate

-

Aliphatic polyisocyanate

-

Crosslinkers

-

Polyisocyanate

-

Hardeners

-

Polyisocyanurate

-

Isocyanate

-

Reactive system

Material:

Coatings, paints & inks:High functional, Weather resistant, Easy mixing, Ultra-low monomer, Waterborne

Adhesives:Moisture resistant, Ultra-low monomer, Waterborne, Heat activated

General Characterization:

Hydrophilically modified, aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI).

As the hardener/binder component for high-quality waterborne polymer dispersions and as an additive to improve the property level of waterborne coating and adhesive systems.

With respect to its composition, the product corresponds to the following sections of the U.S. FDA’s guidelines Title 21 CFR: Section 175.105 “Adhesives”.

Storage Conditions:

– Storage in original sealed Covestro container.

– Recommended storage temperature: 0 – 30 °C.

– Protect from moisture, heat and foreign material.

General information: Hydrophilic isocyanates are very moisture-sensitive and react with water to form carbon dioxide and insoluble ureas. The containers must always be kept tightly closed. The access of water in all forms (moist air, solvents, moist containers) must be prevented, because the generation of carbon dioxide can lead to dangerous increases in pressure. Storage at higher temperatures will result in increase of color and viscosity. Due to the raw materials, the product may show visible turbidity caused by the cold. This turbidity occurs at approx. + 5 °C and is reversible when heated to room temperature. The product properties are not affected.

Sampling

No data available

Technical Properties & Datasheets

Characteristics:

Property Name |

Test Method |

Unit |

Value |

Flash point |

DIN EN 22719 |

°C |

226 |

Equivalent weight |

approx. 230 |

||

Density |

DIN 51757 |

g/ml |

approx. 1.16 |

Specifications:

Property Name |

Test Method |

Unit |

Value |

NCO content |

M105-ISO 11909 |

% |

18.2 ± 0.5 |

Color value (Hazen) |

M017-EN 1557 |

≤ 60 |

|

Viscosity at 23 °C |

M014-ISO 3219/A.3 |

mPa*s |

4,000 ± 1,500 |

Monomeric HDI |

M106-ISO 10283 |

< 0.10 |

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

HDI Waterborne DIC 5500

HDI Waterborne DIC 5500

ABOUT:

The product data shown here are not sales specifications. When you import/use the product, you need to confirm whether the regulations of the country/region are applicable or not. Please refer to SDS concerning safety and handling of the product.

Description:

Water dispersible polyisocyanate hardener.

Applications:

Industrial coatings.

Protective coatings.

Wood coatings.

Hardener for 2K waterborne polyurethane coatings.

Key features:

Dispersibility in water.

Stability in water.

Compatible with main resins.

Characteristics:

Solvent |

Methoxypropyl acetate |

Solids content, % |

79.0 – 81.0 |

Viscosity, Gardner |

G – M |

Acid value on solution, mgKOH/g |

– |

OH value on solution, mgKOH/g |

13.0 – 14.0 (NCO content, %) |

EEW, g/eq |

– |

pH |

– |

Color, Gardner |

– |

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

HDI Waterborne WanHua 278

HDI Waterborne WanHua 278

Product Description:

Aquolin 278 is a water dispersible polyisocyanate based on hexamethylene diisocyanate(HDI). In combination with waterborne polyurethane, polyacrylate, etc., it can be used for water-borne coatings. Thanks to its low viscosity and ease of handmixing, Aquolin 278 can be used to prepare “solvent-free hardener” in order to produce ultralow VOC coatings. After addition of Aquolin 278, the ready-to-use mixture must be used within the pot life.

Properties:

-

Matting effect.

-

Excellent water dispersibility.

-

Excellent weather resistance.

Characteristic data*

Property |

Value |

Unit |

Method |

Appearance |

Colorless to yellowish transparent liquid |

||

NCO content |

22.5±0.5 |

% |

GB/T 12009.4-2016 |

Viscosity |

1500-3500 |

mPa·s |

Brookfield LV, 63#/3rpm,25°C |

Color APHA |

<80 |

GB/T 1722-1992 |

|

Monomericisocyanate |

≤ 0.2 |

% |

GB/T 18446-2009 |

Flash point |

~196 |

°C |

GB/T 5208 |

Density |

~1.16 |

g/cm3 |

GB/T 4472-2011 |