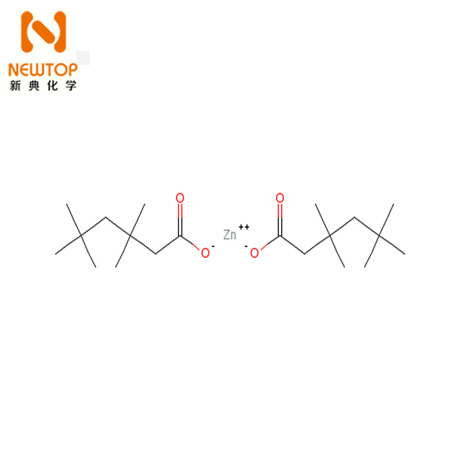

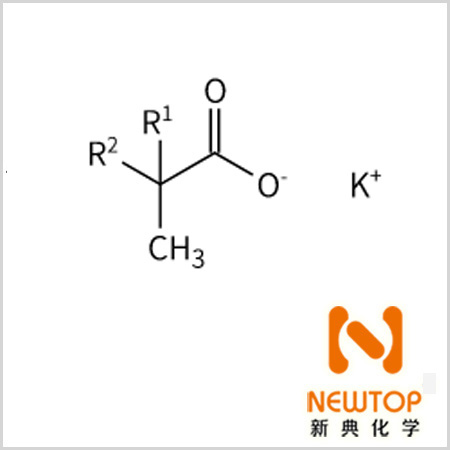

Organic Mercury Replacement Catalyst

NT CAT E-AT is especially developed for environmentally friendly two-component non-foaming polyurethane elastomer runners, completely different from the commonly used amine-tin catalysts, with its own unique foam inhibition function, which can shield the trace moisture contained in the polyurethane raw materials to a large extent (polyether polyols can be used without high-temperature vacuum dewatering), and can completely avoid the phenomena of bulging, blistering and cracking of the product even in humid and rainy weather, which is very similar to the organic mercury-lead catalytic properties. The characteristics are very similar to the catalytic performance of organic mercury and lead.

Storage and transportation:

Should be sealed and stored in a dry, cool and ventilated warehouse

Packing:

180KG/drum Storage: it is recommended to store in dry and cool area with proper ventilation. Please fasten the package cover as soon as possible after the original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

[email protected] |

Telephone: |

86-021-5657 7831 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |