PC5 catalyst/Polyurethane catalyst PC5

Overview:

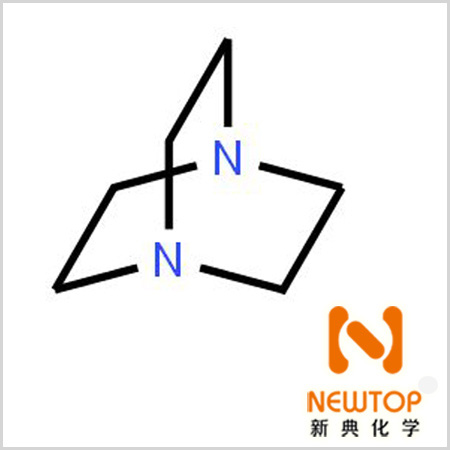

Pentamethyldiethylenetriamine is a highly active catalyst for polyurethane reactions, which mainly catalyzes the foaming reaction, but is also used to balance the overall foaming and gelation reactions. It is widely used in various polyurethane rigid foams, including polyisocyanurate sheet rigid foams. Pentamethyldiethylenetriamine is a chemical substance with the molecular formula C9H23N3. It is a highly efficient catalyst for polyurethane soft foams and is used in the formulation of soft foams, and also as a co-catalyst for hard foams to improve the fluidity of PU foams for large capacity refrigerators.

Alias: Pentamethyldiethylenetriamine, hard foam catalyst PC-5, PC5 catalyst, PC5

Chinese name N,N,N,N,N-Pentamethyldiethylenetriamine

English name N,N,N’,N”,N”-Pentamethyldiethylenetriamine

Alias 1,1,4,7,7-Pentamethyldiethylenetriamine

CAS No. 3030-47-5

Alias N,N,N′,N″,N″-Pentamethyldiethylenetriamine, hard foam catalyst PC-5, PC5 catalyst, catalyst AM-1, PMDETA, hard foam catalyst AM-1

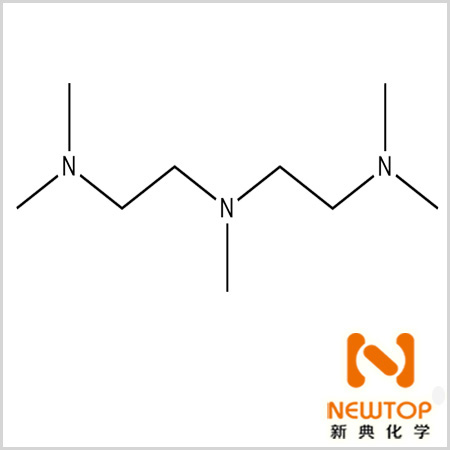

Molecular weight C9H23N3

Chemical formula C9H23N3

Molecular weight 173.3

Melting point -20℃

Boiling point 198℃

Solubility Soluble in water, ether and alcohol solvents.

Appearance Colorless or yellowish transparent liquid

Flash Point 53℃

MDL No.: MFCD00014876

Refractive index: 1.442(lit.)

Basic Information:

Chemical name: N,N,N′,N′,N″-pentamethyldiethylenetriamine

Alias: Pentamethyldiethylenetriamine

Abbreviation: PMDETA

English name: N,N,N′,N′,N″-pentamethyldiethylenetriamine.

Molecular Formula: C9H23N3

Relative molecular mass 173.3

CAS No. 3030-47-5

Physicochemical properties:

Pentamethyldiethylenetriamine is colorless to light yellow clear liquid, easily soluble in water, product purity is generally 98.0%, its typical physical properties are: viscosity (25 ℃) 2mPa.s, relative density (20 ℃) 0.8302-0.8306, flash point (closed cup) 72 ℃ or so, flash point (PMCC) 83.3 ℃, boiling range of 196-201 ℃ or 70-80 ℃ (1100Pa ), vapor pressure (21℃) 0.29*133Pa, freezing point <-20℃. Explosion Limit:Lower Limit 1.1%,Upper Limit 5.6%. Refractive index 1.4435±0.0005,pH=11.0

Characteristics and Uses:

Pentamethyldiethylenetriamine is a highly active catalyst for polyurethane reaction, it catalyzes the foaming reaction mainly, and is also used to balance the overall foaming and gel reaction. It is widely used in various polyurethane rigid foams, including polyisocyanurate sheet rigid foams. Due to its strong foaming effect, it can improve the foam fluidity, so it improves the product production process and increases the production volume, and it is often used together with DMCHA and so on. Pentamethyldiethylenetriamine is used alone as a catalyst for polyurethane foam formulations or in combination with other catalysts. When used alone as a hard foam catalyst, the dosage range is 1.0-2.0 parts per 100 parts of polyol.

In addition to being used in rigid foam formulations, pentamethyldiethylenetriamine can also be used in the production of polyether-based polyurethane flexible block and molded foams. For example, 70% of pentamethyldiethylenetriamine is mainly used in the formulation of flexible foam products, the catalyst is active, the foaming speed is fast, and the products have high toughness as well as high load-bearing properties. In the soft foam every 100 parts of polyether the catalyst 0.1-0.5 parts can get better results. It can also be used as auxiliary catalyst for hard foam.

Pentamethyldiethylenetriamine quaternary ammonium salt is a delayed catalyst for soft foam, used to prolong the foam whitening time, suitable for complex shaped foam products and box-type foaming process, improve the structure of the bubble holes, and improve the quality of molding. Its own dosage range is quite wide, and the change of dosage has no obvious effect on the emulsion time; however, the increase of dosage can shorten the foam rising time, and can shorten the curing time.

Hazard statement

Hazard Code:T

Hazard class:22-24-34

Safety Class:26-36/37/39-45

UN Number:UN2734

Storage and transportation:

Should be kept sealed and stored in a dry, cool and ventilated warehouse

Packaging:

200KG/drum Storage:It is recommended to store in dry and cool area with proper ventilation. Please fasten the package cover as soon as possible after the original package to waterproof

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

[email protected] |

Telephone: |

86-021-5657 7831 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |