N,N-Diisopropylethylamine CAS7087-68-5

N,N-Diisopropylethylamine

- Ethyldiisopropylamine,

3-METHYL-1-BUTINE-3-OL;

BIOTECHGRADESOLVENT,99.5%;

DIPEA,

Ethyldiisopropylamine,

Hünig’s base

CAS Number:7087-68-5

EC Number:230-392-0

MDL number:MFCD00008868

| Appearance | Colorless to Light yellow clear liquid |

| Purity(GC) | min. 99.0 % |

| Quality Level | 200 |

| Assay | ≥99% |

| form | liquid |

| refractive index | n20/D 1.414 (lit.) |

| Melting Point | -45 °C |

| Boiling Point | 127 °C |

| density | 0.742 g/mL at 25 °C (lit.) |

| Specific Gravity | 0.92 |

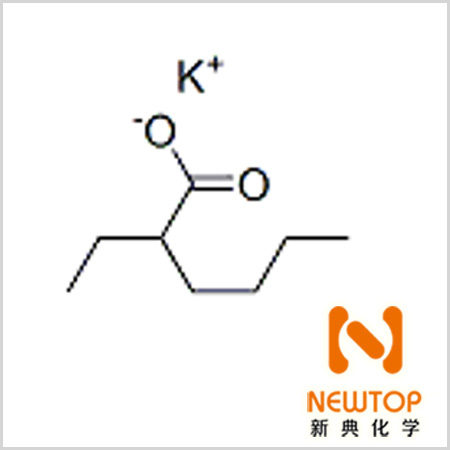

| Molecular Formula / Molecular Weight | C8H19N = 129.25 |

| Flash point | 12 °C |

| Refractive Index | 1.41 |

| Solubility in water | Insoluble |

| Solubility (soluble in) | Alcohol |

| Condition to Avoid | Air Sensitive |

| CAS | 7087-68-5 |

| MDL Number | MFCD00008868 |

| Explosion limit | 0.7 – 6.3 %(V) |

| pH value | 12.3 (H₂O, 20 °C) (as an emulsion) |

| Viscosity kinematic | 0.88 mm2/s (20 °C) |

| Vapor pressure | 14 hPa (20 °C) |

| HS Code | 2921 19 99 |

General description

N,N-Diisopropylethylamine, also known as Hünig′s base, is a sterically hindered amine. It is a non-nucleophilic base commonly employed for substitution reactions.It acts as an activator for chiral iridium N, P ligand complexes, which can be utilized in the hydrogenation of α, β-unsaturated nitriles. The influence of varying concentration of N,N-diisopropylethylamine on the synthesis of olvanil in the presence of lipase catalyst has been investigated.

Application

N,N-Diisopropylethylamine may be used in the synthesis of mannosylated ovalbumin peptides.

TBDPS protection of Alcohols using tert-Butylchlorodiphenylsilane.

BOM protection of Alcohols using Benzyloxymethyl Chloride.

Storage and transportation:

Should be sealed and stored in a dry, cool and ventilated warehouse

Package:

200KG/drum Storage: It is recommended to store in dry and cool area with proper ventilation. Please fasten the lid as soon as possible after original packing to prevent the mixing of other substances such as moisture from affecting the product performance. Do not inhale dust and avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and wash them before use. Maintain good hygiene habits.

Email us: [email protected]