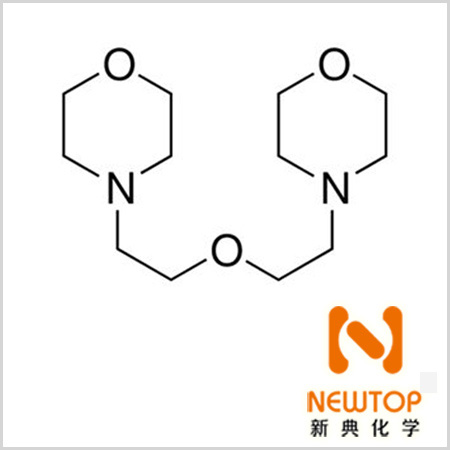

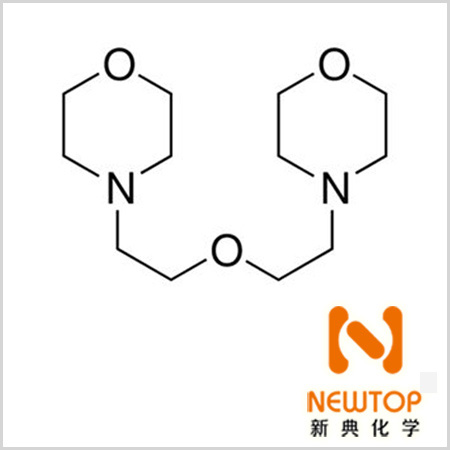

High Quality CAS 6425-39-4 / 2,2-dimorpholinodiethylether / DMDEE / 2-dimorpholinodiethylether

Overview:

Bis-morpholine diethyl ether is used as a catalyst (or curing agent) in one-component polyurethane systems (e.g., one-component polyurethane caulk, one-component polyurethane foam adhesive, one-component polyurethane grouting material, etc.). Since one-component polyurethane prepolymers need long time storage stability, bismorpholine diethyl ether plays a key role in the stabilization and polymerization of polyurethane prepolymers, which also puts forward extremely high requirements on the quality of bismorpholine diethyl ether products.

Basic information:

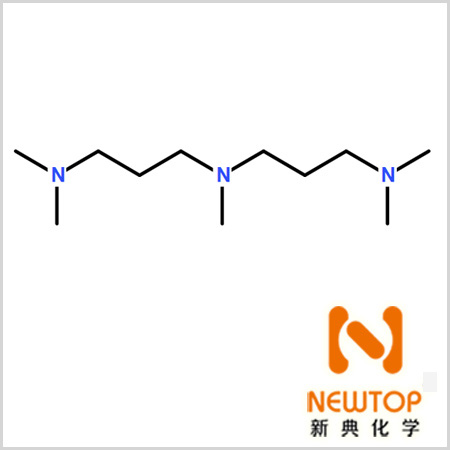

Name: Bismorpholine diethyl ether

Bis-morpholino diethyl ether is used as a catalyst (or curing agent) in one-component polyurethane systems (e.g., one-component polyurethane caulk, one-component polyurethane foam adhesive, one-component polyurethane grouting material, etc.). Since one-component polyurethane prepolymers need long time storage stability, bismorpholine diethyl ether plays a key role in the stabilization and polymerization of polyurethane prepolymers, which also puts forward very high requirements on the quality of bismorpholine diethyl ether products.

Alias: 2,2-bis-morpholino diethyl ether, dimorpholine diethyl ether, bis(2,2-morpholinoethyl) ether.

Abbreviation: DMDEE, Bis(2,2-morpholinodiethyl) ether, CAS 6425-39-4, Catalyst DMDEE, Polyurethane catalyst DMDEE, Foaming catalyst DMDEE DMDEE, Dabco DMDEE, Jeffcat DMDEE, Lupragen N106, PC CAT DMDEE, Addocat 118, Foaming Catalyst DMDEE, Polyurethane Foaming Catalyst DMDEE

English name: 2,2-dimorpholinodiethylether;bis(2,2-morpholinoethyl)ether.

Molecular Formula: C12H24N2O3

Relative molecular mass: 244.0

CAS No.: 6425-39-4

Physical and chemical properties:

Bimorpholinodiethyl ether Appearance Colorless to light yellow liquid, soluble in water.

Typical physical property indexes are:

Viscosity (25℃): 18mPa-s.

Relative density (25℃): 1.06;

Boiling point: greater than 225°C;

Melting point: less than -28°C;

Flash point (TCC): 146°C;

Amine value: 7.9~8.1mmol/g.

The purity of industrial products is generally ≥99% or ≥98%, and the water content is ≤0.5%.

Applications:

2,2-Bis-morpholino diethyl ether is suitable for water curing system, it is a strong foaming catalyst, due to the site resistance effect of amino group, it can extend the storage period of NCO component, suitable for the catalytic reaction of NCO and water in TDI, MDI, IPDI and other systems; 2,2-Bis-morpholino diethyl ether is mainly used in one-component rigid polyurethane foam system, it can be also used in polyether-type and polyester-type polyurethane soft foam, It can also be used in polyether-type and polyester-type polyurethane soft foam, semi-rigid foam, CASE materials, etc. The added amount accounts for 0.3-0.55% of the polyether/ester component.

Bis(morpholino)diethyl ether is an amine catalyst suitable for curing systems. It is a strong foaming catalyst, which can make the NCO-containing components have a long storage period due to the site-blocking effect of the amine. It is mainly used in one-component rigid polyurethane foam systems, but can also be used in polyether-type and polyester-type polyurethane flexible foams, semi-rigid foams and CASE materials.

Safety:

Bimorpholinodiethyl ether can burn eyes and skin. In case of contact with eyes, eyes should be washed immediately with plenty of water and medical attention should be sought immediately. In case of skin contact, the infected area should be washed with water immediately. During material handling, it is advisable to wear eye protection against splashing and butyl rubber gloves, rubber lab coat and rubber boots.

Bimorpholinodiethyl ether 6425-39-4 DMDEE Dabco DMDEE Jeffcat DMDEE Lupragen N106 PC CAT DMDEE Addocat 118

Storage and transportation:

Should be sealed and stored in a dry, cool and ventilated warehouse, sealed and stored at room temperature.

Packaging:

200KG/drum Storage: it is recommended to store in dry and cool area with proper ventilation. Please fasten the package cover as soon as possible after the original packaging to prevent moisture and other substances from mixing and affecting the performance of the product. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. Shower and change clothes after work. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

[email protected] |

Telephone: |

86-021-5657 7831 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |