Octyl Tin Mercaptide/CAS 26401-97-8

Overview:

Product Name: Octyl Tin Mercaptide,CS 26401-97-8,Octyl Tin Mercaptide

Product code: OTM-17N

Item Index

Main content ≥98

Tin content (%) ≥14.0

Sulfur content (%) 8.8-9.5

Chromaticity(Pt-Co) ≤300#

Basic information:

1.English name: Octyl Tin Mercaptide (OTM)

2.CAS No.: 26401-97-8

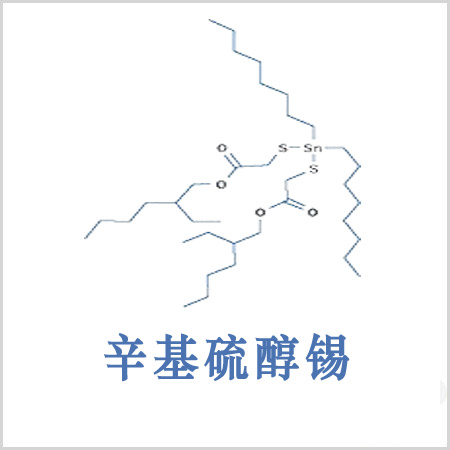

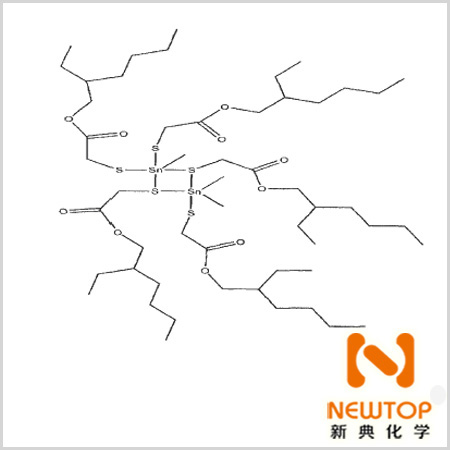

3.Molecular Formula: C36H72O4S2Sn

4.Properties: light yellow transparent oily liquid, slightly sulfide odor.

Product name: Octyltin mercaptide (OTM-17N)

CAS No.: 26401-97-8

Alias: Octyltin mercaptide (OTM-17N)

Molecular Formula: C36H72 O4 S2 Sn

EINECS No.: 247-666-0

Content: 98

Use: Medicine, chemical industry

Appearance: see the object

Heavy metal: 10

Usage:

This product has good fluidity and strong thermal stability. It is suitable for calendering, extrusion and injection molding of PVC food packaging rigid film and sheet. It is one of the heat stabilizers of PVC.

Storage and transportation:

It should be sealed and stored in dry, cool and ventilated warehouse

Packing:

200KG/drum Storage: it is recommended to store in dry and cool area with proper ventilation. Please fasten the packaging cover as soon as possible after the original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Store in a cool and dry place, keep the container sealed and avoid contact with oxides. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothing separately and wash before use. Maintain good hygiene practices.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

[email protected] |

Telephone: |

86-021-5657 7831 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |