dibutyl stannane diacetate/bis (acetoxy) dibutyl stannane

Overview:

Dibutyltin diacetate is a light yellow or colorless transparent liquid with acetic acid odor.

Product name: Dibutyl tin diacetate 1067-33-0

English name: Dibutyl tin diacetate

Alias: Dibutyltin diacetate; Dibutylstannane diacetate; Bis(acetoxy)dibutyltin; Dibutyltin diacetate; Dibutyltin acetate; Dibutyltin diacetate; Dibutyltin acetate; Dibutyltin acetate

Product Code: DBTDA

CAS No.:1067-33-0

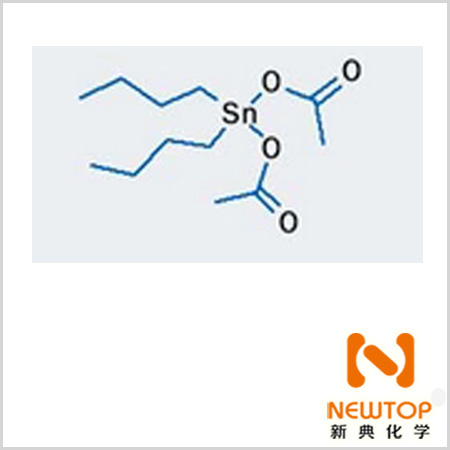

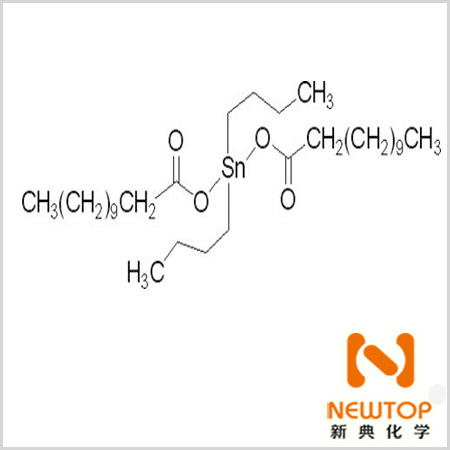

Molecular Formula:C12H24SnO4

Chinese name Dibutyltin diacetate

Foreign Name Dibutyl tin diacetate

Alias Dibutyl tin diacetate

CA Registry Number 1067-33-0

Molecular Formula: (C4H9)2Sn(OOCCH3)2

Molecular weight: 351

Specific gravity (H2O=1): 1.3

Melting point: 10°C

Physical Properties

Molecular formula: (C4H9)2Sn(OOCCH3)2

Molecular weight: 351.0

Specific gravity (H2O=1): 1.30

Melting point: 10℃

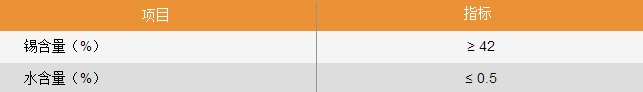

Quality index: Appearance: colorless or light yellow transparent liquid Sn content: 32.5±0.5%

Relative density (25℃): about 1.30

Sn content: 32.0-33.8%

Chemical properties:

Melting point :7-10 °C(lit.)

Boiling point :142-145 °C10 mm Hg(lit.)

Density :1.32 g/mL at 25 °C(lit.)

Vapor density :12 (vs air)

Vapor pressure :1.3 mm Hg ( 25 °C)

Refractive index :n20/D 1.471(lit.)

Flash Point :>230 °F

Water solubility :insoluble

CAS Database:1067-33-0(CAS DataBase Reference)

NIST: Dibutyltin diacetate(1067-33-0)

EPA: Stannane, bis(acetyloxy)dibutyl-(1067-33-0)

Uses:

Colorless or light yellow transparent liquid, below 10 ℃ is solid then semi-solid

Gel catalyst, mainly used as room temperature silicone rubber curing catalyst, especially for deacetic acid type silicone products; its characteristic is that the catalytic speed is faster than dibutyltin dilaurate, it can be used in polyurethane elastomer, sprayed rigid polyurethane foam, hard foam high resilience molded foam, etc.. In order to reduce its acetic acid odor can be used in conjunction with dibutyltin dilaurate, usually adopts dibutyltin diacetate: dibutyltin dilaurate is 1:9 or 2:8. this product should be capped immediately after use, it is easy to hydrolyze when exposed to air, and solid precipitated at the mouth of the bottle. It is also used as a catalyst for polyurethane coatings.

Storage:

Storage should be dry, temperature above 10 ℃ is preferred. Below 10 ℃ precipitated crystals, heating melting does not affect the use of the effect.

Transportation:

Store in sealed containers and in a cool, dry place. The storage place must be locked and the key must be given to the technical experts and their assistants for safekeeping. The storage place must be kept away from oxidizing agents and away from water sources.

Packed in general-purpose plastic and sprayed iron drums or glass containers and transported in accordance with general chemical management regulations.

Packaging:

Packing: it is preferable to use glass containers, plastic containers, chlorine corrosion-resistant metal utensils to contain, sealed and stored. Store in a cool and dry place, keep the container sealed and avoid contact with oxides. Do not inhale dust, avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothing separately and wash before use. Maintain good hygiene practices.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

[email protected] |

Telephone: |

86-021-5657 7831 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |