Category: Amine Catalyst

Amine Catalyst

HDI trimer show respect DH-100

HDI trimer show respect DH-100

ABOUT:

Product Class: Isocyanate

DURANATE TKA-100 by Asahi Kasei is a hexamethylene diisocyanate (HDI) trimer. Acts as a curing agent for urethanes. Exhibits excellent color retention,weatherability and outstanding performance. Possible applications could be coatings for automotive, architectural, industrial, consumer electronic and information technology. Other applications of DURANATE TKA-100 may include gravure, offset and screen inks. Shows superior weatherability, good chemical & abrasion resistance, good compatibility and drying properties.

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

HDI trimer HDT-100

HDI trimer HDT-100

ABOUT:

Tolonate™ HDT is a medium viscosity, solvent-free aliphatic polyisocyanate, used to produce 2K polyurethane coatings with superior performances.

BENEFITS:

-

Abrasion Resistance,

-

Hardness,

-

Weathering Resistance

APPLICATIONS:

-

Coatings & Adhesives,

-

Adhesives & Sealants,

-

Automotive OEM & refinish,

-

General Industry,

-

Transportation

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

HDI trimer HX-100

HDI trimer HX-100

ABOUT

CHEMICAL CHARACTERIZATION:

HDI based modified polyisocyanate, containing isocyanurate

FORM:

Non-solvent, 100% of solid content.

USES:

Hardener for two-component, non-yellowing type of polyurethane paint with excellentweathering ability.

CHARACTERISTICS:

Coronate-HX |

|

appearance |

Pale yellow liquid |

NCO content (%) |

20.5-22.0 |

Solid content (%) |

100 |

Viscosity 25°C (Gardner No.)(mPa.s) |

X – Z21,290 – 3,620 |

Color (Gardner No.) |

≤1 |

Monomer HDI(%) |

≤0.4 |

FEATURES:

CORONATE HX is a hardener for non-yellowing type of PU paints, with superiorperformance to conventional biuret or adduct types of hardeners. CORONATE HX iswidely accepted in the paint industry for various applications, such as motor bike parts,automotive parts, automotive finishing, wood finishes, etc. This is because of itsresistance to high heat, high solubility in solvents and good compatibility with polyols.

APPLICATIONS:

The combination of CORONATE HX with acrylic polyols produces non-yellowingtype of’ paint with excellent weathering ability and resistance against ultra-violet rays.by which its original color could be long sustained. This two-component type ofpaint is applied for automotive refinishes, industrial purposes, etc.

The combination of CORONATE HX with alkyd polyols results in two-componenttype of paint, which is applied for industrial purpose, wood finishes, etc.

The addition of CORONATE HX to some nitro-cellulose based or polyurethane basedpaints distinctively improves their physical properties, such as chemical resistance tosolvents. However, it is necessary to test the compatibility for each combination andgreat care should be taken during testing.

HANDLING INSTRUCTIONS

STORAGE CONDITIONS:

CORONATE HX should always be kept in a closed container at room temperaturefor long period of storage. This is to prevent any contact with moisture in the air.since this product is a chemical compound and is highly active with hydroxyl groups.This product should be stored indoors at room temperature (15-25°C).

AT THE TIME OF USE / RE-PACKING:

The reaction of water with the NCO groups in this product causes not only theformation of insoluble products such as urea groups, but also CO, gas, whichincreases the pressure in a closed container, thus resulting in an expansion of thecontainer.Ihe operation for partial use of this product or emptying of a drum should becarriedout with great care in order to prevent any contamination with moisture.The operation to transfer this product into another container should be done under adry atmosphere, then sealed with dry nitrogen before sealing.

DILUTION WITH SOLVENTS:

When this product has to be diluted with solvents, the water content of the solventshould be as low as possible, and great care should be taken during dilution in orderto prevent contamination with water. In addition, this operation should be carriedout under a dry atmosphere.In case of this product needs to be diluted with the desired solvent, the DilutionStability Test of the final formulation under the application conditions is stronglyrecommended.There is a possibility of precipitation, generation of gel-type substance or haze, if thedilution formulation was inappropriate.

Please note that all the dilution work is under customer’s responsibility

SAFETY PRECAUTIONS:

-

Care must be taken when handling CORONATE HX as it contains active isocyanateand solvent.

-

Please refer to MSDS concerning its hazards, proper use, and handling before workingwith this product.T

-

his product is flammable. Therefore, the use of fire is prohibited in the work area.

-

Appropriate safety measures and protective equipment such as goggles and gloves.should be used when working with this product in order to prevent contact with skin.

-

CORONATE HX is mainly applied for spray coatings. A protective mask should beworn in order to prevent inhalation of spraying mist.

-

CORONATE HX contains below 0.4% of free isocyanate. This value does notincrease even if this product is stored over a long period.

STANDARD PACKING:

CORONATE HX |

220 kgs ( 200L iron drum ) |

|

|

20 kgs( 18L tin can) |

E_mail us : [email protected]

HDI Low viscosity TPA-100

HDI Low viscosity TPA-100

Type :

Aliphatic Polyisocyanate (HDI Trimer)

Features:

# High NCO content

# Lower viscosity

# Good coated film appearance

# Good weather resistance

# Low residual monomer

Applications:

# Two-component applications# Plastic coatings# Auto refinish coatings

# Automobile, motorcycle ; base coat and top coat# Heavy duty coatings

Typical properties:

Appearance |

Colorless to slightly yellowish clear liquid |

Non-volatile |

100 wt% |

Solvent |

NONE |

NCO content |

23.1 wt% |

Viscosity |

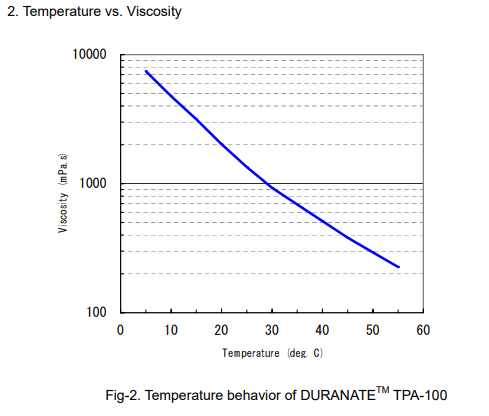

1400 mPa .s at 25°C |

Color value |

<1 (Gardner) |

NCO equivalent weight |

Approx.182 |

Flash point |

252°C |

Density at 20°c |

1.17 |

These values provide general information and are not part of the productspecifications.

Stability / thinnability:

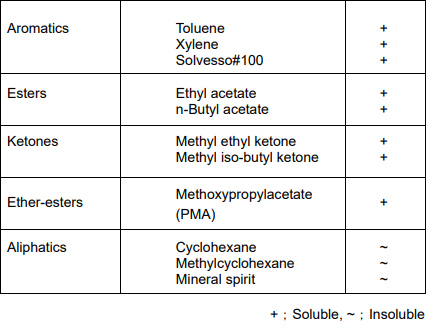

DURANATETM TPA-100 can be thinned with esters,

ketones and aromatichydrocarbons such as ethyl acetate, butyl acetate, methoxypropylacetate(PMA), methylethyl ketone, methyl-butyl ketone, cyclohexanone,toluene, xylene, Solvesso #100 andmixture thereof. Generally speaking, it has good compatibility with thesolventmentioned. However, the solutions formed must be tested for their storage stability.Only PU grade solvents can be used (max. 0.05% water, absence of reactive groupssuch as hydroxyl or amines groups). Aliphatic hydrocarbons such as hexane.cyclohexane, methylcyclohexanes and mineral spirits, are unsuitable as solventsbecause of their poor solubility.

DURANATETM TPA-100 should not be thinned to below a solid content of 40%.Prolonged storage of solution with lower solid content may result in turbidity andsedimentation.

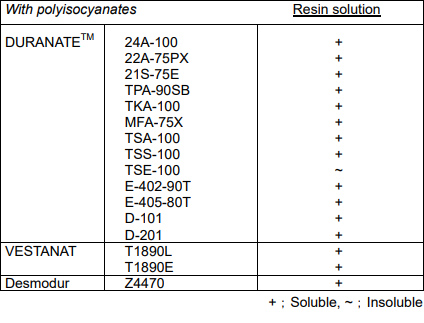

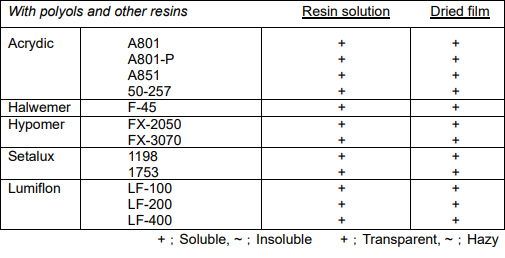

Compatibility:

Mixing ratio of DURANATETM TPA-100 with polyols is based on NCO/OH equivalentratio of 1/1.

Storage:

DURANATETM TPA-100 is sensitive to moisture and should therefore always be storedin sealed containers.

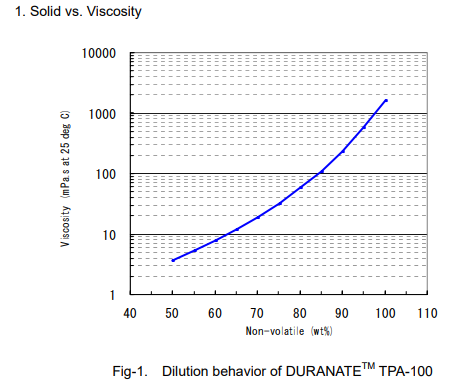

Characteristics of iscosity:

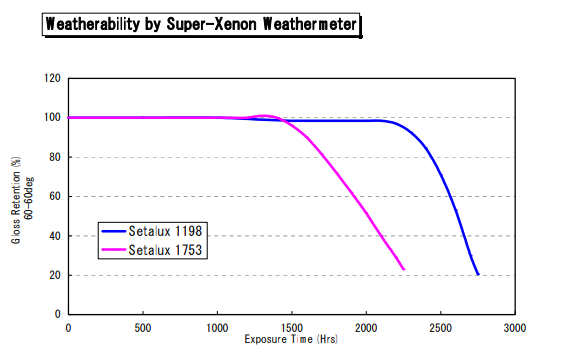

Weatherability:

Fig-3. Weatherability of DURANATETM TPA-100 with acrylic polyol

Polyol; Setalux 1198 & 1753 (Nuplex Resins)Weathered by Super-Xenon Weathermeter

E_mail us : [email protected]

HDI Waterborne AsahiKasei WE50-100

HDI Waterborne AsahiKasei WE50-100

ABOUT:

DURANATE™ WE50-100 by Asahi Kasei is a water dispersible hexamethylene diisocyanate (HDI). Acts as a curing agent for urethanes. Exhibits excellent color retention and outstanding performance. Provides good elasticity, excellent good chemical & abrasion resistance, good adhesion and drying properties. Possible applications could be coatings for automotive, architectural, industrial, consumer electronic and information technology. Other applications of DURANATE™ WE50-100 may include gravure, offset and screen inks.

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

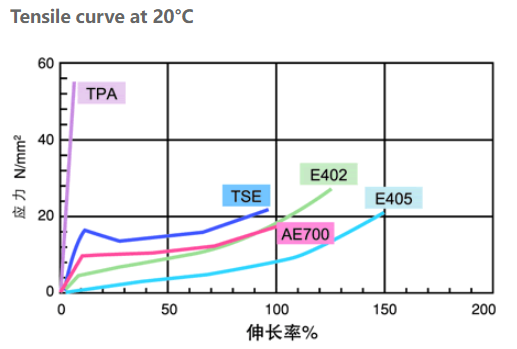

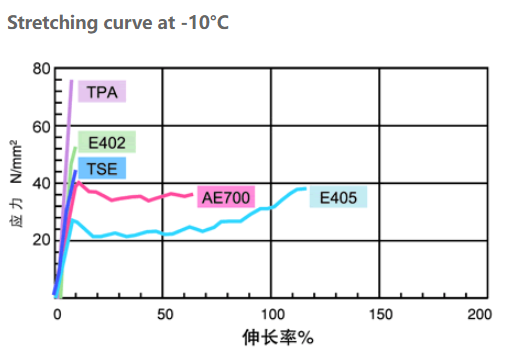

HDI Elastic type Covesro E402-90T E405-80T TSE-100

HDI Elastic type Covesro E402-90T E405-80T TSE-100

Product introduction:

Coating films with elasticity and excellent weather resistance can be obtained without adding plasticizers.

It is suitable for elastic substrates such as plastic, leather, rubber and other materials that require tensile properties.

DonadTMmodel |

solid content

|

NCO%

|

Viscosity

|

solvent |

Features |

E402-90T |

90 |

8.5 |

1200 |

Toluene |

elasticity |

E405-80T |

80 |

7.1 |

230 |

Toluene |

low temperature elasticity |

TSE-100 |

100 |

12.0 |

1650 |

— |

Soluble in low polar solvents |

AE700-100 |

100 |

11.9 |

800 |

— |

low temperature elasticitySoluble in low polar solvents |

* Please inquire about changing the dilution solvent

E_mail us : [email protected]

HDI Elastic type Covesro N3800

HDI Elastic type Covesro N3800

ABOUT:

Aliphatic polyisocyanate (flexibilizing HDI trimer).As the hardener component for lightfast polyurethane coating systems.

Product Types:

-

HDI

-

PIC

-

Aliphatic polyisocyanate

-

Crosslinkers

-

Polyisocyanate

-

Hardeners

-

Polyisocyanurate

-

Isocyanate

Material:

Coatings, paints & inks:High functional, Weather resistant, Solventborne, Flexible, Elastic

Technical Properties & Datasheets

Characteristics:

Property Name |

Test Method |

Unit |

Value |

Viscosity at 23 °C |

M014-ISO 3219/A.3 |

mPa*s |

6,000 ± 1,200 |

NCO content |

M105-ISO 11909 |

% |

11.0 ± 0.5 |

Color value (Hazen) |

M017-EN 1557 |

≤ 80 |

|

Monomeric HDI |

M106-ISO 10283 |

% |

≤ 0.25 |

Specifications:

Property Name |

Test Method |

Unit |

Value |

Flash point |

DIN 22 719 |

°C |

approx. 235 |

Equivalent weight |

approx. 382 |

||

Viscosity at 25 °C |

DIN EN ISO 3219/A.3 |

mPa*s |

approx. 5,500 |

Density at 20 °C |

DIN EN ISO 2811 |

g/ml |

approx. 1.12 |

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

IPDI Quick drying Evonik T1890E

IPDI Quick drying Evonik T1890E

ABOUT:

VESTANAT® T 1890 is a cycloaliphatic polyisocyanate crosslinker with remarkably short curing cycles even at ambient temperatures.

POLYISOCYANATE CROSSLINKERS IN 2K SYSTEMS:

-

Combination with a resin component right before application

-

Reaction starts immediately after mixing the polyisocyanate with the resin component

-

Reaction leads to a 3D network with a high durability

Benefits:

-

Low viscosity

-

Excellent compatibility & high reactivity

-

Durability against environmental impacts

-

UV resistant, lightfast and very good gloss retention

-

First-class chemical resistance

-

High reactivity even at ambient temperature

-

Short curing cycles

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

IPDI Quick drying Covesro Z4470 SN

IPDI Quick drying Covesro Z4470 SN

ABOUT:

Aliphatic polyisocyanate (IPDI trimer).As the hardener component for lightfast polyurethane coating systems and as an additive resin for alkyd spray coatings.

Product Types:

-

PIC

-

IPDI

-

Aliphatic polyisocyanate

-

Crosslinkers

-

Polyisocyanate

-

Hardeners

-

Polyisocyanurate

Material:

Coatings, paints & inks:Fast curing, Weather resistant, Solventborne, Hard

General Characterization:

Aliphatic polyisocyanate (IPDI trimer).

As the hardener component for lightfast polyurethane coating systems and as an additive resin for alkyd spray coatings.

Storage Conditions:

– Storage in original sealed Covestro container.

– Recommended storage temperature: 0 – 30 °C.

– Protect from moisture, heat and foreign material.

General information: The product is sensitive to moisture. Storage at higher temperatures will result in increase of color and viscosity. Storage at significant lower temperatures will result in solidification. This solidification is reversible by briefly heating the product without adversely affecting the quality of the product.

Technical Properties & Datasheets

Characteristics:

Property Name |

Test Method |

Unit |

Value |

Density at 20 °C |

DIN EN ISO 2811 |

g/ml |

approx. 1.05 |

Equivalent weight |

approx. 360 |

||

Flash point |

DIN 53 213/1 |

°C |

approx. 45 |

Viscosity at 25 °C |

M014-ISO 3219/A.3 |

mPa*s |

approx. 1700 |

Specifications:

Property Name |

Test Method |

Unit |

Value |

Viscosity at 23 °C |

M014-ISO 3219/A.3 |

mPa*s |

2,000 ± 600 |

Non-volatile content (0.2 g/1 h/120 °C) |

M020-ISO 3251 |

% |

70 ± 2 |

NCO content |

M105-ISO 11909 |

% |

11.9 ± 0.4 |

Monomeric IPDI |

M106-ISO 10283 |

% |

< 0.35 |

Color value (Hazen) |

M017-EN 1557 |

≤ 60 |