Author: admin

HDI Low Viscosity Covesro N3400

HDI Low Viscosity Covesro N3400

About:

Product Types

-

HDI

-

PIC

-

Aliphatic polyisocyanate

-

Crosslinkers

-

Polyisocyanate

-

Hardeners

-

Polyisocyanurate

-

Isocyanate

Material:

Coatings, paints & inks:Weather resistant, Low viscous, Solvent-free, Easy mixing, Waterborne

General Characterization:

Aliphatic polyisocyanate (HDI uretdione).

As the hardener component for lightfast polyurethane coating systems.

Logistics and Handling

Storage Conditions:

– Storage in original sealed Covestro container.

– Recommended storage temperature: 0 – 30 °C.

– Protect from moisture, heat and foreign material.

General information: The product is sensitive to moisture. Storage at higher temperatures will result in increase of color and viscosity.

Sampling:

No data available

Packaging Type:

No data available

Technical Properties & Datasheets

Characteristics:

Property Name |

Test Method |

Unit |

Value |

Flash point |

DIN 22 719 |

°C |

approx. 180 |

Density at 20 °C |

DIN EN ISO 2811 |

g/ml |

approx. 1.14 |

Viscosity at 25 °C |

M014-ISO 3219/A.3 |

mPa*s |

approx. 140 |

Equivalent weight |

approx. 193 |

Specifications:

Property Name |

Test Method |

Unit |

Value |

Color value (Hazen) |

M017-EN 1557 |

≤ 80 |

|

Monomeric HDI |

M106-ISO 10283 |

% |

≤ 0.3 |

Viscosity at 23 °C |

M014-ISO 3219/A.3 |

mPa*s |

175 ± 75 |

NCO content |

M105-ISO 11909 |

% |

21.8 ± 0.7 |

E_mail us : [email protected]

HDI Low Viscosity Covesro N3600

HDI Low Viscosity Covesro N3600

Characterization :

Aliphatic polyisocyanate (low-viscosity HDI trimer).

Use as the hardener component for flexible, lightfast polyurethane coating systems.

Specification:

Property |

Value |

Unit of measurement |

Method |

NCO content |

23.0 ± 0.5 % |

% |

M105-ISO 11909 |

Viscosity at 23 °C |

1,200 ± 300 |

mPa·s |

M014-ISO 3219/A.3 |

Color value (Hazen) |

≤ 40 |

M017-EN 1557 |

|

Monomeric HDI |

≤ 0.25 |

% |

M106-ISO 10283 |

Other data*:

Property |

Value |

Unit of measurement |

Method |

Viscosity at 25 °C |

approx. 1,100 |

mPa·s |

M014-ISO 3219/A.3 |

Equivalent weight |

approx. 183 |

||

Flash point |

approx. 158 |

°C |

DIN 53 213/1 |

Density at 20 °C |

approx. 1.16 |

g/ml |

DIN EN ISO 2811 |

Solubility / thinnability :

Desmodur® N 3600 can be thinned with esters, ketones and aromatic hydrocarbons suchas ethyl acetate, butyl acetate, methoxypropylacetate,acetone, methyl ethyl ketone, methyl isobutyl ketone, cyclohexanone, toluene,xylene, solvent naphtha® 100 and mixtures thereof.Generally speaking, it has good compatibility with the solvents listed. However,the solutions formed must be tested for their storage stability. Only PU grade solvents should be used (max. 0.05 % water, absence of reactive groups such as hydroxyl or amino groups). Aliphatic hydrocarbons are unsuitable as solvents.

Desmodur®N 3600 should not be thinned to below a solids content of 40 %.

Prolonged storage of a solution with a lower binder content may result in

turbidity and sedimentation.

Compatibility:

Generally speaking, Desmodur®N 3600 can be mixed with the following products: Aliphatic polyisocyanates such as Desmodur®N 100, N 75, N 3200,ultra N 3300, N 3400 and Desmodur®Z 4470; aromatic polyisocyanates such as Desmodur® L/ultra L, HL and IL/ultra IL; polyester polyols such as Desmophen® 670 and polyacrylates. However, the compatibility of the combinations used should alwaysbe tested.

Desmodur® N 3600 is not compatible with branched polyester polyols such as Desmophen®651 or polyether polyols such as Desmophen® 1380 BT.

Properties / Applications:

Desmodur® N 3600 is used primarily as the hardener component for lightfast two-component polyurethane coatings with high resistance to chemicals and weathering, very good gloss retention and outstanding mechanical properties.

Preferred co-reactants are polyacrylate or polyester polyols.

The main applications for systems based on Desmodur®N 3600 areair- and force-drying coatings for automotive OEM, automotive refinishing,transportation, industrial finishing and plastics.

On account of its low viscosity, Desmodur®N 3600 is particularly suitable for the formulation of high-solids coatings and can also beused as the hardener for aqueous two-component polyurethane coatings.

Storage :

– Storage in original sealed Covestro container.

– Recommended storage temperature: 0 – 30 °C.

– Protect from moisture, heat and foreign material.

General information: The product is sensitive to moisture. Storage at higher temperatureswill result in increase of color and viscosity.Storage at significant lower temperatures will result in solidification.This solidification is reversible by briefly heating the product without adversely affecting the quality of the product.

Storage time :

Covestro represents that, for a period of nine months following the day of shipment as stated in the respective transport documents,the product will meet the specifications orvalues set forth in section “specifications or characteristic data” above, what ever is applicable, provided that the product is stored in full compliance with the storage conditions set forth in and referenced under section “storage” above and is otherwise handled appropriately.

The lapse of the nine months period does not necessarily mean that the product no longer meets specifications or the set values. However, prior to using said product, Covestrorecommends to test such a product if it still meets the specifications or the set values.Covestro does not make any representation regarding the product after the lapse of thenine months period and Covestro shall not be responsible or liable in any way for the product failing to meetspecifications or the set values after the lapse of the nine months period.

E_mail us : [email protected]

HDI trimer DN-980BA

HDI trimer DN-980BA

ABOUT:

DN-980BA is a methyl methoxyisocyanate curing agent.

Typical Physical Properties:

appearances |

Clear Liquid |

Active substance content |

90% |

Viscosityat25°C(mm²/s) |

700±300 |

color value |

≤1 |

disassociateHDI(Wt%) |

≤0.5 |

NCO Content (%) |

19.8±0.2 |

fluids |

butyl acetate |

solubility |

DN-980BA is soluble in solvents such as ethyl acetate, butyl acetate enzyme, and ketones. |

Properties and Uses:

-

High solubility in solvents, good compatibility with polyols

-

High crosslink density

-

Good resistance to yellowing and weathering, good flexibility

Scope of application:

Automobile refinishing paints, motorcycle paints wood paints, metal, plastic coatings,Heavy duty anticorrosive coatings

Storage:

Synthetic Leather Coating, DN-980BA is a highly active compound and should be stored out of direct sunlight, away from ignition sources, radiation, moisture, and in airtight containers.

Safety:

Handle with care, avoid contact with skin and eyes. For additional information, please refer to the Material Safety Data Sheet.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

HDI trimer AsahiKasei TKA-90SB

HDI trimer AsahiKasei TKA-90SB

ABOUT:

Product Class: Isocyanate

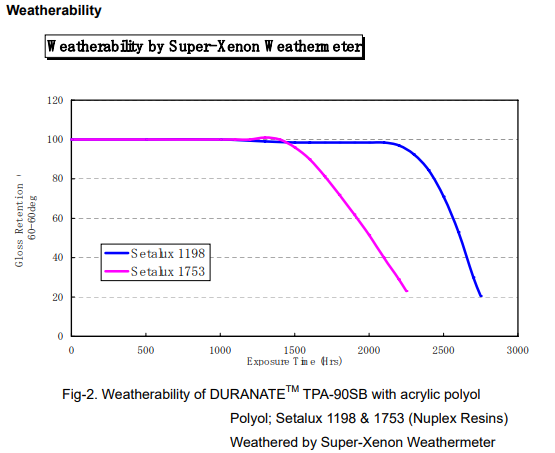

DURANATE TKA-90SB by Asahi Kasei is a hexamethylene diisocyanate (HDI) trimer compatible with urethanes. Acts as a curing agent. Exhibits excellent weatherability, good chemical & abrasion resistance, good compatibility and drying properties. Offers excellent color retention and outstanding performance. Suitable for coatings for automotive, architectural, industrial, consumer electronic and information technology. Other applications of DURANATE TKA-90SB may include gravure, offset and screen inks.

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

HDI trimer AsahiKasei TPA-90SB

HDI trimer AsahiKasei TPA-90SB

Type:

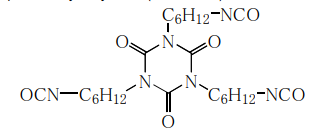

Aliphatic Polyisocyanate (HDI Trimer)

Features:

# High NCO content

# Lower viscosity

# Good coated film appearance

# Good weather resistance

# Low residual monomer

Applications:

# Two-component applications

# Plastic coatings

# Auto refinish coatings

# Automobile, motorcycle ; base coat and top coat

# Heavy duty coatings

Typical properties:

Appearance |

Colorless to slightly yellowish clear liquid |

Non-volatile |

90 wt% |

Solvent |

Solvent naphtha (petroleum),light arom. / Butyl acetate=1/1 |

NCO content |

20.9 wt% |

Viscosity |

310 mPa·s at 25℃ |

Color value |

< 1 (Gardner) |

NCO equivalent weight |

Approx.201 |

Flash point |

60℃ |

Density at 20℃ |

1.13 |

These values provide general information and are not part of the productspecifications.

Stability/ thinnability:

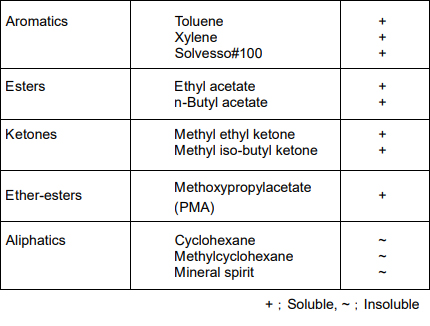

DURANATETM TPA-90SB can be thinned with esters, ketones and aromatic.hydrocarbons such as ethyl acetate, butyl acetate, methoxypropylacetate(PMA), methylethyl ketone, methyl-butyl ketone, cyclohexanone, toluene, xylene, Solvesso #100 andmixture thereof. Generally speaking, it has good compatibility with the solventmentioned. However, the solutions formed must be tested for their storage stability.Only PU grade solvents can be used (max. 0.05% water, absence of reactive groupssuch as hydroxyl or amines groups). Aliphatic hydrocarbons such as hexane.cyclohexane, methylcyclohexanes and mineral spirits, are unsuitable as solventsbecause of their poor solubility.

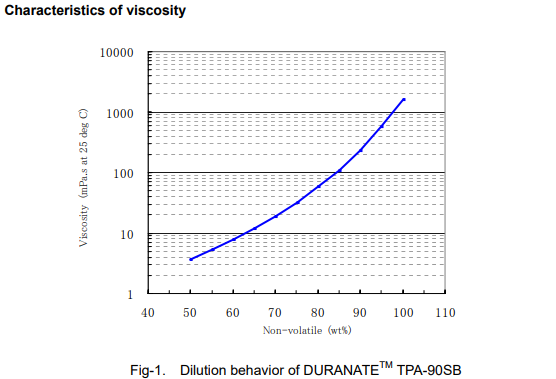

DURANATETM TPA-90SB should not be thinned to below a solid content of 40%.Prolonged storage of solution with lower solid content may result in turbidity andsedimentation.

Compatibility:

Mixing ratio of DURANATETM TPA-90SB with polyols is based on NCO/OH equivalentratio of 1/1 .

Storage:

DURANATETM TPA-90SB is sensitive to moisture and should therefore always bestored in sealed containers.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

Covestro Desmodur N3390 BA/SN HDI trimer curing agent standard light-resistant curing agent

| Type | aliphatic polyisocyanate (hexamethylene diisocyanate trimer) |

| Form of Supply | about90%Butyl acetate/100Solvent naphtha Oil (1:1) solution |

| Purpose | used as light-resistant polyurethane coating curing agent combination |

Product Specifications

| Features | Value | Measurement unit | Method |

| NCOcontent | 19.6±0.3 | % | DIN EN ISO 11909 |

|

Method |

|||

| Viscosity@25℃ | about500 | mPa.s | DIN EN ISO 3219/A.3 |

| equivalent | about214 | ||

| Flashpoint | about50℃ | DIN 53 213/1 | |

| Density@20℃ | about1.13 | g/ml | DIN EN ISO 2811 |

*The above values are general information and do not belong to the product specification.

Solubility/Dilution

Curing agent N3390 can be used in esters, ketones, and aromatic solvents such as: ethyl acetate, butyl acetate, methoxypropyl acetate, acetone, methyl ethyl ketone, methyl isobutyl Dilute with ketone, cyclohexanone, toluene, xylene, 100# solvent naphtha and their mixture. Miscibility with the above solvents is generally good. However, the storage stability of the prepared solution must be tested. Polyurethane grade solvents should be used (less than 0.05% water, no hydroxyl or amino reactive groups). Aliphatic hydrocarbons are not suitable as solvents.

Curing agent N3390 should not be diluted below 40% solids. For solutions with low base material content, turbidity and precipitation will occur after long-term storage.

Compatibility

Curing agent N3390 is generally miscible with the following products. That is: curing agent N100, N75, N3200, N3400, N3600 and curing agent Z4470 type aliphatic isocyanate; curing agent L, HL and IL type aromatic polyisocyanate; Desmophen 670 type polyester polyol; Desmophen A type polyacrylate. However, the compatibility of the prepared solutions must be tested. Hardener N 3390 is not compatible with branched polyester polyols such as Desmophen 651 or polyether polyols such as Desmophen 550U.

Features/Applications

Curing agent N3390 is mainly used as a curing agent component of light-fast two-component polyurethane coatings, which have excellent chemical resistance and weather resistance, outstanding gloss retention and Excellent mechanical properties. Ideal co-reactants are polyacrylate or polyester polyols.

The coating system formulated with curing agent N3390 is suitable for self-drying or baking, and is used for the finishing of automobile original paint (OEM), automobile repair, transportation, industrial products and plastics.

Save

Curing agent N3390 is sensitive to moisture, so it should be stored in the original airtight container. If stored under normal conditions, this product has a shelf life of at least 6 months.

Security

Flammable, may cause sensitization by skin contact. Harmful to aquatic organisms, may cause long-term adverse effects in the aquatic environment. Contains isocyanates.

Content less than 0.05%, no hydroxyl or amino active groups). Aliphatic hydrocarbons are not suitable as solvents.

Curing agent N3390 should not be diluted below 40% solids. For solutions with low base material content, turbidity and precipitation will occur after long-term storage.

Compatibility

Curing agent N3390 is generally miscible with the following products. That is: curing agent N100, N75, N3200, N3400, N3600 and curing agent Z4470 type aliphatic isocyanate; curing agent L, HL and IL type aromatic polyisocyanate; Desmophen 670 type polyester polyol; Desmophen A type polyacrylate. However, the compatibility of the prepared solutions must be tested. Hardener N 3390 is not compatible with branched polyester polyols such as Desmophen 651 or polyether polyols such as Desmophen 550U.

Features/Applications

Curing agent N3390 is mainly used as a curing agent component of light-fast two-component polyurethane coatings, which have excellent chemical resistance and weather resistance, outstanding gloss retention and Excellent mechanical properties. Ideal co-reactants are polyacrylate or polyester polyols.

The coating system formulated with curing agent N3390 is suitable for self-drying or baking, and is used for the finishing of automobile original paint (OEM), automobile repair, transportation, industrial products and plastics.

Save

Curing agent N3390 is sensitive to moisture, so it should be stored in the original airtight container. If stored under normal conditions, this product has a shelf life of at least 6 months.

Security

Flammable, may cause sensitization by skin contact. Harmful to aquatic organisms, may cause long-term adverse effects in the aquatic environment. Contains isocyanates.

HDI trimer NPU HXR-90SB

HDI trimer NPU HXR-90SB

ABOUT:

constitute |

Polyisocyanates modified with HDI-based isocyanate trimers |

Supply Form |

100% solids |

use |

Used as a non-yellowing curing agent for two-component coatings with good weathering resistan |

Typical property indicators:

C-HXLV |

Coronate-HXR |

Coronate-HX |

C-HK |

|

appearances |

Light yellow liquid |

|||

NCO content (%) |

22.5-23.9 |

21.6-22.1 |

20.5-22.0 |

19.3-20.7 |

Solid content (%) |

100 |

100 |

100 |

100 |

Viscosity 25°C (mm2/s) |

800-1500 |

1700-3300 |

1300-3600 |

3620-14800 |

Color number (APHA NO.) |

<40 |

<40 |

<80 |

<80 |

Free HDI content (wt%) |

<0.2 |

<0.2 |

<0.6 |

<1.0 |

Specific gravity 20°C |

1.17 |

1.17 |

1.16 |

1.17 |

Characteristics :

CORONATE HXR, HXLV, HX or HK are non-yellowingcuring agents for polyurethane coatings with better properties than diurethane condensate urethane adducts. CORONATE HXR, HXLV, HX or HK are widely used in motorcycle parts, automobile refinishing and wood coatings because of their good heat resistance and good compatibility with polyols and solvents.

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area withproper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possibleafter original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucousmembrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintaingood hygiene practices.

E_mail us : [email protected]

HDI Low Viscosity Covesro XP2840

HDI Low Viscosity Covesro XP2840

Characterization :

Aliphatic polyisocyanate based on hexamethylene diisocyanate.

As the hardener component for lightfast, weather-stable coating systems.

Form supplied :100 %

Characteristic data*

Property |

Value |

Unit of measurement |

Method |

NCO content |

approx. 23.0 |

% |

DIN EN ISO 11 909 |

Viscosity at 23 °C |

approx. 500 |

mPa·s |

DIN EN ISO 3219/A.3 |

Color value (Hazen) |

< 80 |

DIN EN 1557 |

|

Monomeric HDI |

≤ 0.26 |

% |

DIN 55 956 |

*These values are provisional. Binding supply specifications will no be available until the final product data sheet is published.

Other data**:

Property |

Value |

Unit of measurement |

Method |

Viscosity at 25 °C |

approx. 450 |

mPa·s |

DIN EN ISO 3219/A.3 |

Equivalent weight |

approx. 183 |

g |

|

Flash point |

183 |

°C |

DIN EN 22 719 |

Density at 20 °C |

1.15 |

g/cm3 |

DIN EN ISO 2811 |

**These values provide general information.

Solubility / thinnability :

The product is compatible with the following solvents:

ethyl acetate, butyl acetate, 1-methoxypropylacetate-2, acetone, methyl ethyl ketone, methyl isobutyl ketone, cyclohexanone, toluene, xylene,solvent naphtha® 100 and mixtures thereof.

Aliphatic hydrocarbons are unsuitable as solvents.

Desmodur® XP 2840 should not be thinned to below a solids content of 40 % by weight. Prolonged storage of a solution with lower binder content may result in turbidity and sedimentation. Storage stability of the thinned product should be tested in each case.

Compatibility :

Desmodur®XP 2840 can be blended with most Desmodur® grades, such as:Desmodur®N 75, N 100, N 3200, N 3300, N 3390, N 3400, N 3600, N 3900,Z 4470, HL and IL. Compatibility is generally good with hydroxyfunctional polyesters and polyethers (Desmophen®grades) as well as hydroxy acrylates.

It is incompatible with Desmophen® 650 and 651.

Properties / Applications :

As a particularly low-viscosity polyisocyanate, Desmodur® XP 2840 is particularly well suited for the formulation of high-solids coatings for general industrial coating, automotive refinishing, transportation and plastics coating applications.

Storage:

– Storage in original sealed Covestro container.

– Recommended storage temperature: > 0 – 30 °C.

– Protect from moisture, heat and foreign material.

General information : The product is sensitive to moisture. Storage at higher temperatures will result in increase of color and viscosity.

Storage time :

Covestro represents that, for a period of nine months following the day of shipment as stated in the respective transport documents, the product will meet the specifications or values set forth in section “specifications or characteristic data” above, what ever is applicable, provided that the product is stored in full compliance with the storage conditions set forth in and referenced under section “storage” above and is otherwise handled appropriately.

The lapse of the nine months period does not necessarily mean that the product no longer meets specifications or the set values. However, prior to using said product, Covestro recommends to test such a product if it still meets the specifications or the set values. Covestro does not make any representation regarding the product after the lapse of the nine months period and Covestro shall not be responsible or liable in any way for the product failing to meet specifications or the set values after the lapse of the nine months period.

E_mail us : [email protected]

HDI Low Viscosity Covesro XP2860

HDI Low Viscosity Covesro XP2860

Characterization :

Aliphatic polyisocyanate based on hexamethylene diisocyanate.

As the hardener component for lightfast, weather-stable coating systems.

Form supplied:100 %

Characteristic data*:

Property |

Value |

Unit of measurement |

Method |

NCO content |

approx. 20.0 |

% |

M105-ISO 11909 |

Viscosity at 23 °C |

approx. 500 |

mPa·s |

M014-ISO 3219/A.3 |

Color value (Hazen) |

≤ 80 |

M017-EN 1557 |

|

Monomeric HDI |

≤ 0.16 |

% |

M106-ISO 10283 |

*These values are provisional. Binding supply specifications will not be available until the final product data sheet is published.

Other data**:

Property |

Value |

Unit of measurement |

Method |

Viscosity at 25 °C |

approx. 450 |

mPa·s |

DIN EN ISO 3219/A.3 |

Equivalent weight |

approx. 215 |

||

Flash point |

193 |

°C |

DIN EN 22 719 |

Density at 20 °C |

1.106 |

g/cm3 |

DIN EN ISO 2811 |