Month: October 2023

HDI Quick drying Vencorex X FD 90B

HDI Quick drying Vencorex X FD 90B

Description:

Fast drying aliphatic polyisocyanate based on high functionality hexamethylene diisocyanate trimer (HDI homopolymer), supplied at 90% solids in butyl acetate.

Suggested Uses:

Hardener of fast drying non-yellowing two-pack polyurethane coatings for car repair,marine and protective, ACE and machinery, aerospace, general industry, automotive OEM and plastic parts.

Specifications:

Colour |

≤60 HAZEN (APHA) |

Viscosity at 25°C |

2000±1000 mPa.s |

NCO (on delivery form) |

17.4 ±0.6 % |

Solids content |

90.0±1.0 % |

Hexamethylene diisocyanate monomer (HDI) |

< 0.5% |

The analytical methods are available upon request

Physical Properties:

Appearance |

Clear liquid |

Bulk density at 25°C |

1130 kg/m3 approx. |

Flash point (closed cup) |

48°C approx. |

Equivalent weight (on delivery form) |

240 g approx. |

Solubility:

Soluble in esters, ketones, aromatic hydrocarbons. In most cases, esters/aromatic hydrocarbon mixtures are used.

It is recommended to use “urethane grade” solvents for the dilution (with water content below 300 ppm).

Applications:

Tolonate™ X FD 90 B is typically used as a crosslinker of hydroxylated polymers,especially polyesters and polyacrylic polyols, to prepare fast drying twocomponent polyurethanes coatings showing excellent outdoor durability and mechanical properties in conjunction with outstanding resistance to solvents,abrasion and chemical products.

Packaging and transport

Packaging (please contact our sales team for more details):

-

US origin : 225 kg net metallic drum

-

France origin: Deliveries of 900 kg net weight pallets (4 drums of 225 kg netweight).

-

Other packaging: upon request

Transport

-

For more precise details, please refer to the safety data sheet

Storage conditions and shelf-life

-

Tolonate™ X FD 90 B is sensitive to moisture and should be kept in its original container or in a volume tank under dry nitrogen blanketing, for example.

-

Appropriate storage for nine months does not normally affect the product in any way if it is stored in its sealed original drums in proper storage conditions, at temperatures below 40°C.

Flammability and safety instructions:

Before handling this product please refer to its safety data sheet

E_mail us : [email protected]

HDI Diourea AsahiKasei 22A-75PX

HDI Diourea AsahiKasei 22A-75PX

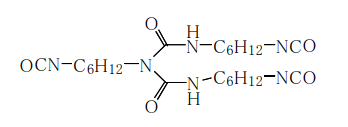

Type :

Aliphatic polyisocyanate (HDI Biuret)

Features:

# Good coated film appearance

# Good adhesion

# Good weather resistance

Applications:

# Two-component applications

# Plastic coatings

# Auto refinish coatings

# Automobile, motorcycle; base coat and top coat# Heavy duty coatings

Typical properties:

Appearance |

Colorless to slightly yellowish clear liquid |

Non-volatile |

75 wt% |

Solvent |

Methoxypropylacetate (PMA)Xylene=1/1 |

NCO content |

16.5 wt% |

Viscosity |

210mPa .s at 25°C |

Color value |

<1 (Gardner) |

NCO equivalent weight |

Approx.254 |

Flash point |

39°C |

Density at 20°C |

1.07 |

These values provide general information and are not part of the product specifications.

Stability / thinnability:

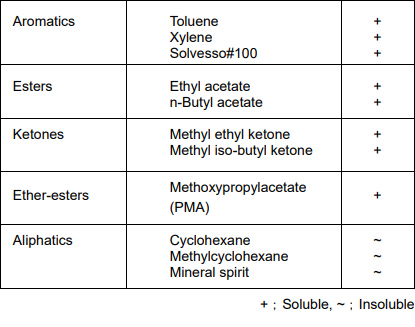

DURANATETM 22A-75PX can be thinned with esters, ketones and aromatic.hydrocarbons such as ethyl acetate, butyl acetate, methoxypropylacetate (PMA),methyl ethyl ketone, methyl-butyl ketone, cyclohexanone, toluene, xylene, Solvesso#100 and mixture thereof. Generally speaking, it has good compatibility with thesolvents mentioned. However, the solutions formed must be tested for their storagestability.

Only PU grade solvents can be used (max. 0.05% water, absence of reactive groupssuch as hydroxyl or amines groups). Aliphatic hydrocarbons such as hexane,cyclohexane, methylcyclohexanes and mineral spirits, are unsuitable as solventsbecause of their poor solubility.

DURANATETM 22A-75PX should not be thinned to below a solid content of 40%.Prolonged storage of solution with lower solid content may result in turbidity andsedimentation.

Compatibility:

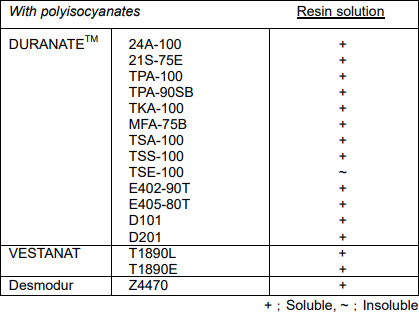

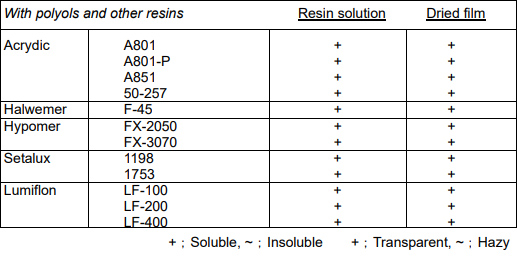

Mixing ratio of DURANATETM 22A-75PX with polyols is based on NCO/OH equivalentratio of 1/1 .

Storage:

DURANATETM 22A-75PX is sensitive to moisture and should therefore always bestored in sealed containers.

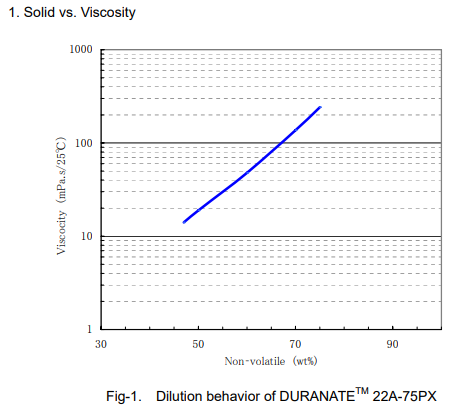

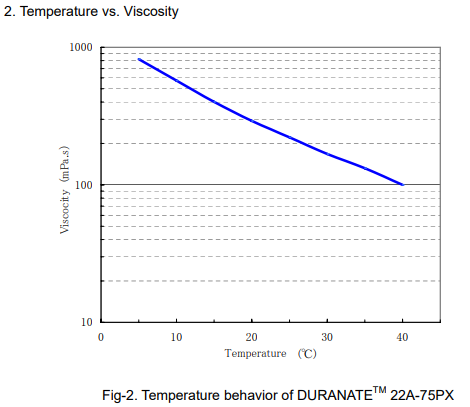

Characteristics of viscosity

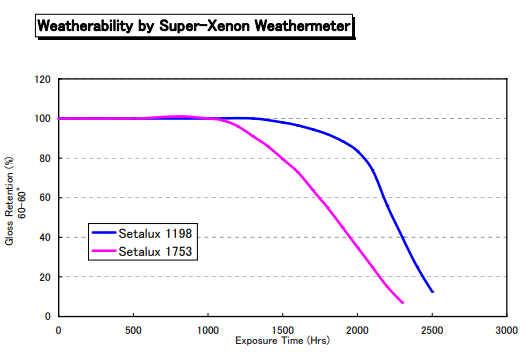

Weatherability

E_mail us : [email protected]

HDI Diourea TOSOH HX-T

HDI Diourea TOSOH HX-T

ABOUT:

CORONATE® HX-T by Tosoh is polyisocyanate. It is a non-yellowing compound containing HDI rings, modified by multifunctional alcohols. Used as a binding agent for substrates. Suitable for PU coatings. Designed for automotive, construction, wooden, metal, plastic, rubber, concrete, paper and leather coatings. It can be used in combination with NIPPOLANS or polyols (polyesters, epoxies, acrylics and other resins.

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

HDI Quick drying Covesro N3790 BA

HDI Quick drying Covesro N3790 BA

ABOUT:

Aliphatic polyisocyanate (high functional HDI trimer).As the hardener component for lightfast, rapid-drying polyurethane coating systems.

Product Types:

-

HDI

-

PIC

-

Aliphatic polyisocyanate

-

Crosslinkers

-

Polyisocyanate

-

Hardeners

-

Polyisocyanurate

-

Isocyanate

Material:

Coatings, paints & inks:High functional, Weather resistant, Solventborne

General Characterization:

Aliphatic polyisocyanate (high functional HDI trimer).

As the hardener component for lightfast, rapid-drying polyurethane coating systems.

Technical Properties & Datasheets

Characteristics

Property Name |

Test Method |

Unit |

Value |

Equivalent weight |

approx. 236 |

||

Density at 20 °C |

DIN EN ISO 2811 |

g/ml |

approx. 1.13 |

Viscosity at 25 °C |

DIN EN ISO 3219/A.3 |

mPa*s |

approx. 1,600 |

Flash point |

DIN 53 213/1 |

°C |

approx. 42 |

Specifications:

Property Name |

Test Method |

Unit |

Value |

Monomeric HDI |

DIN EN ISO 10 283 |

% |

< 0.23 |

Non-volatile content (2.2 g / 120 min / 100 °C) |

DIN EN ISO 3251 |

% |

90 ± 1 |

NCO content |

DIN EN ISO 11 909 |

% |

17.8 ± 0.5 |

Color value (Hazen) |

DIN EN 1557 |

≤ 40 |

|

Viscosity at 23 °C |

DIN EN ISO 3219/A.3 |

mPa*s |

1,800 ± 500 |

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

HDI closed AsahiKasei TPA-B80X

HDI closed AsahiKasei TPA-B80X

Type:

Blocked aliphatic polyisocyanate based on hexamethylene diisocyanate

Features:

# Good curability

#Excellent weatherability

# Good storage stability

Applications:

# One-component applications

# Top coat for automotive OEM

# Primer for automotive OEM

# Coatings for anticorrosive plate

Typical properties:

Appearance |

Colorless to slightly yellowish clear liquid |

Non-volatile |

80 wt% |

Solvent |

Xylene 20 wt% |

Blocked NCO content |

12.5 wt% |

Viscosity |

4,800 mPa . s at 25°C |

Color value |

<1 (Gardner) |

Flash point |

30.8°C (Seta Closed-cup) |

Compatibility:

Mixing ratio of DURANATETM TPA-B80X with polyols is based on NCO/OH equivalentratio of 1/1 .

These values provide general information and are not part of the productspecifications.

Curing properties:

Test conditions:Acrylic polyol; OHV=100 per resin

NCO/OH ratio ;1.0

DBTL; 0.1 wt% per solid

E_mail us : [email protected]

HDI closed TOSOH BI-301

HDI closed TOSOH BI-301

ABOUT:

Coronate® BI-301, in the form of a pale yellow to brownish flakes, is an isocyanate that is masked with blocking agents (E-caprolactam and phenol). This blocked isocyanate can be applied as baking finishes for coil coatings, wire, rubber, plastics, metals, and more.

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

HDI closed Vencorex D2

HDI closed Vencorex D2

Description:

Blocked aliphatic polyisocyanate (HDI homopolymer), supplied at 75 % solids in aromatic solvent.

Specifications:

Colour |

≤40 HAZEN (APHA) |

Viscosity at 25°C |

2500 – 4000 mPa.s |

NCO (available after deblocking) |

11.2 ±0.5 % |

Solids content |

75.0±2.0 % |

Free NCO |

< 0.2 % |

The analytical methods are available upon request

Physical Properties:

Appearance |

Clear liquid |

Bulk density at 25°C |

1060 kg/m3 approx. |

Weight per US gallon |

8.85 lbs approx. |

Flash point (closed cup) |

49°C approx. |

Equivalent weight (on delivery form) |

375 g approx. |

Solubility:

Soluble in esters, ketones, aromatic hydrocarbons. In most cases, esters/aromatic hydrocarbon mixtures are used.

Applications:

Tolonate™ D2 is typically used as a crosslinker of hydroxylated polymers notably polyesters and polyacrylates to prepare heat activated one component polyurethane systems for weatherable coatings giving excellent mechanical properties in conjunction with outstanding resistance to solvents, abrasion and chemical products. Tolonate™ D2 is commonly used in Automotive OEM formulations, can and coil coatings and other general industrial coatings on metal. The curing conditions are generally 20 to 40 minutes at 140-160°C (285-305°F) or 30 to 35 seconds at 320°C (PMT = 232 / 241°C).

Packaging and transport

Packaging (please contact our sales team for more details)

-

US origin: 215 kg net metallic drum

-

France origin: deliveries of 860 kg net weight pallets (4 drums of 215 kg netweight).

-

Other packaging: upon request

Transport:

-

Regulated. For more precise details, please refer to the safety data sheet

Storage conditions and shelf-life:

-

Tolonate™ D2 is not affected by moisture at room temperatue.

-

Appropriate storage for two years does not normally affect Tolonate™ D2 in anyway if it is stored in its sealed original drums inusual storage condition, at temperatures bellow 40°C.

Flammability and safety instructions:

Before handling this product please refer to its safety data sheet

E_mail us : [email protected]

HDI closed Covesro BL 3175 SN

HDI closed Covesro BL 3175 SN

ABOUT:

Blocked aliphatic HDI-polyisocyanate. With Desmophen® grades to formulate lightfast one-component polyurethane stoving coatings; as an additive to improve flexibility and adhesion.

Product Types:

-

HDI

-

PIC

-

Aliphatic polyisocyanate

-

Crosslinkers

-

Polyisocyanate

-

Hardeners

-

Polyisocyanurate

-

Isocyanate

Material:

Coatings, paints & inks:

Solventborne, Flexible, Thermally resistant, Elastic

General Characterization:

Blocked, aliphatic polyisocyanate based on HDI.

In combination with Desmophen® grades to formulate lightfast, one-component polyurethane stoving coatings; as an additive in conventional stoving systems to improve flexibility and adhesion.

Storage Conditions:

– Storage in original sealed Covestro container.

– Recommended storage temperature: 0 – 30 °C.

– Protect from moisture, heat and foreign material.

General information: Storage at higher temperatures will result in increase of color and viscosity. Storage at significant lower temperatures will result in solidification. This solidification is reversible by briefly heating the product without adversely affecting the quality of the product.

Characteristics:

Property Name |

Test Method |

Unit |

Value |

Equivalent weight |

approx. 380 |

||

Density at 20 °C |

DIN EN ISO 2811 |

g/ml |

approx. 1.06 |

Flash point |

DIN 53 213/1 |

°C |

approx. 45 |

Blocked NCO content |

% |

approx. 11.1 |

|

Viscosity at 25 °C |

M014-ISO 3219/A.3 |

mPa*s |

approx. 2,800 |

Specifications:

Property Name |

Test Method |

Unit |

Value |

Color value (Hazen) |

M017-EN 1557 |

≤ 60 |

|

Viscosity at 23 °C |

M014-ISO 3219/A.3 |

mPa*s |

3,300 ± 400 |

Free NCO content, modified |

M105-ISO 11909 |

% |

≤ 0.2 |

Non-volatile content (0.2 g / 60 min / 80 °C) |

M020-ISO 3251 |

% |

75 ± 2 |

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : [email protected]

HDI closed AsahiKasei SBN-70D CAS 34590-94-8

HDI closed AsahiKasei SBN-70D CAS 34590-94-8

ABOUT:

Category : Isocyanate

Industry:

-

Coatings

-

Ink

-

Adhesives

Description:

DURANATE SBN-70D by Asahi Kasei is a low cruing temperature types blocked hexamethylene diisocyanate (HDI) trimer with low baking colanation, Shows lower temperature curing feature particularly in case of thin film thickness. Acts as a curing agent for urethanes. Provides excellent weatherability, good chemical & abrasion resistance, good adhesion and drying properties. Shows excellent color retention and outstanding performance. DURANATE SBN-70D is suitable for applications of automotive, adhesives and coil coating. Possible applications could be coatings for architectural, industrial, consumer electronic and information technology, gravure, offset and screen inks.

Component:

Substance Component Name |

Content* (%) |

CAS NO. |

Blocked polyisocyanate |

Approx. 70 |

included |

dipropylene glycol monomethylether |

Approx.30 |

34590-94-8 |